Filling and capping machines play a crucial role in the packaging industry, ensuring products are safely and accurately filled into bottles with airtight seals. For businesses looking to optimize their production lines, machines like the eye drop filling and capping machine, glass bottle filling and capping machine, and water bottle filling and capping machine offer reliable performance and precision.

The eye drop filling and capping machine is specifically designed for the pharmaceutical and healthcare industries, where precision and hygiene are paramount. These machines handle small-volume bottles, accurately dispensing the liquid with minimal waste while maintaining sterile conditions. The capping mechanism securely seals bottles to prevent contamination and ensure product safety. Ideal for eye drops and similar liquid medications, these machines increase throughput and reduce manual labor without compromising quality.

For industries using glass containers, the glass bottle filling and capping machine provides an excellent solution. Glass bottles require careful handling to avoid breakage and maintain product integrity. These machines are equipped with specialized conveyors and filling nozzles that gently manage glass bottles through the filling process. The capping system ensures tight and consistent seals, which are essential for products such as beverages, pharmaceuticals, and cosmetics packed in glass containers.

When it comes to beverage production, the water bottle filling and capping machine is engineered to meet high-speed demands with consistent accuracy. Whether filling purified water, mineral water, or flavored beverages, these machines streamline the packaging process. They offer flexible configurations to handle different bottle sizes and shapes and incorporate sanitary designs to meet food safety standards. Automated capping systems prevent leaks and maintain product freshness during distribution and storage.

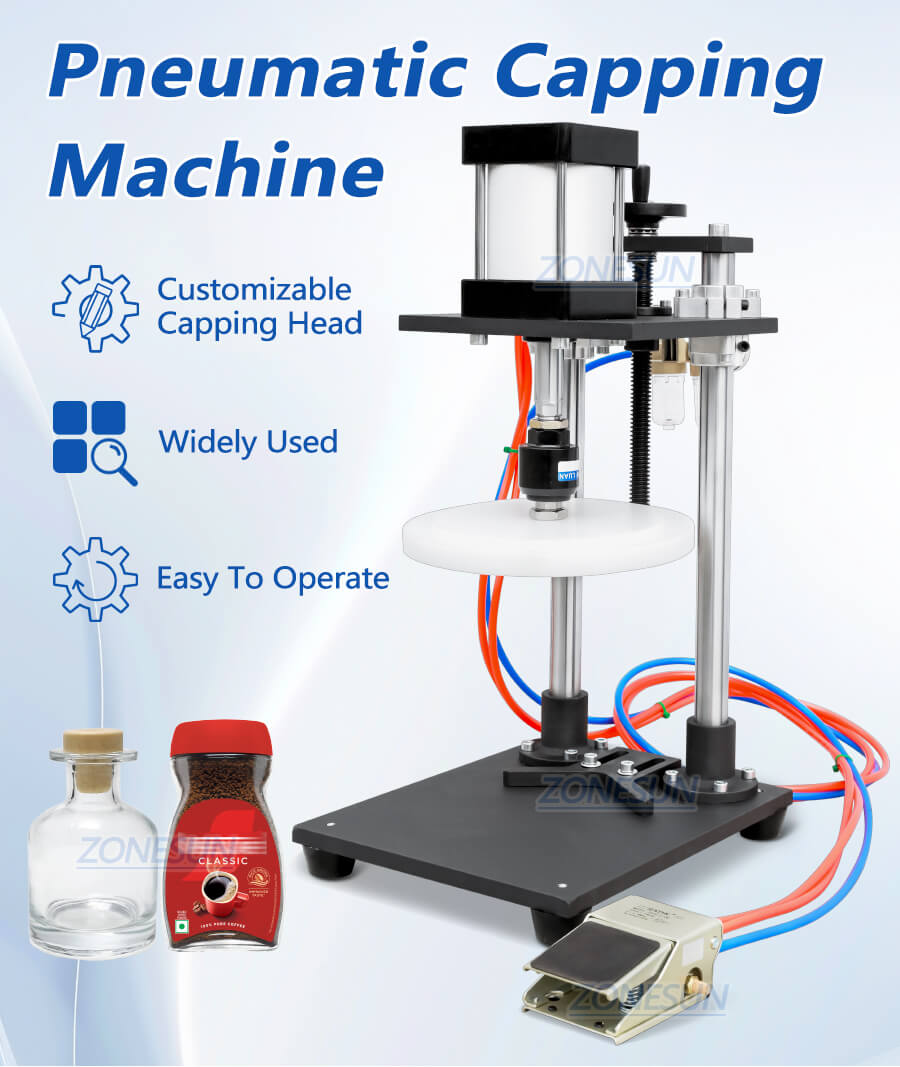

Modern filling and capping machines from platforms like Zonesun integrate user-friendly controls and durable components. Automated features include adjustable filling volumes, speed controls, and sensor-based bottle detection, which help minimize errors and downtime. The machines also facilitate easy cleaning and maintenance, essential for industries with strict hygiene regulations.

Selecting the right filling and capping machine depends on your product type, bottle material, and production volume. For liquid pharmaceuticals requiring sterile environments, an eye drop filling and capping machine is indispensable. If glass packaging is preferred for product presentation or preservation, investing in a glass bottle filling and capping machine ensures careful handling and quality sealing. Beverage manufacturers benefit from water bottle filling and capping machines designed for efficiency and flexibility in high-volume operations.

In addition to precision and speed, these machines contribute to overall cost savings by reducing manual labor, minimizing product waste, and ensuring compliance with industry standards. They are suitable for various production scales, from small batches to large manufacturing lines.

In summary, advanced filling and capping machines are essential assets for any packaging line involving liquid products. Whether filling eye drops, glass bottled liquids, or water, selecting a machine tailored to your needs enhances product quality, boosts production efficiency, and ensures consumer safety.