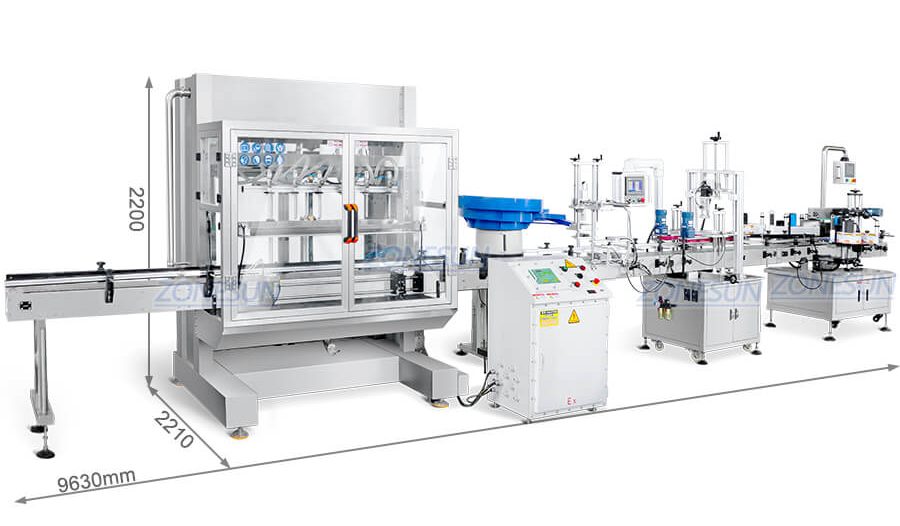

Automatic Ex-proof Liquid Filling Capping Labeling Line

The explosion-proof production line consists of an Ex-proof gravity filling machine, a servo cap feeding capping machine, and a labeling machine. It’s designed for fully automated production of flammable and explosive liquids like acetone, paint, and kerosene.

Share to

Product Description:

The explosion-proof production line consists of an Ex-proof gravity filling machine, a servo cap feeding capping machine, and a labeling machine. It’s designed for fully automated production of flammable and explosive liquids like acetone, paint, and kerosene.

Product Parameters:

| Machine Model | ZS-YTEX1 |

| Machine Voltage | 110/220V 1KW |

| Filling Range | 1000-5000ml |

| Filling Speed | About 10-30 bottles/min (depending on bottle size and filling materials) |

| Filling Nozzle Quantity | 6 (can be customized) |

| Air Consumption | 4kgs*30L |

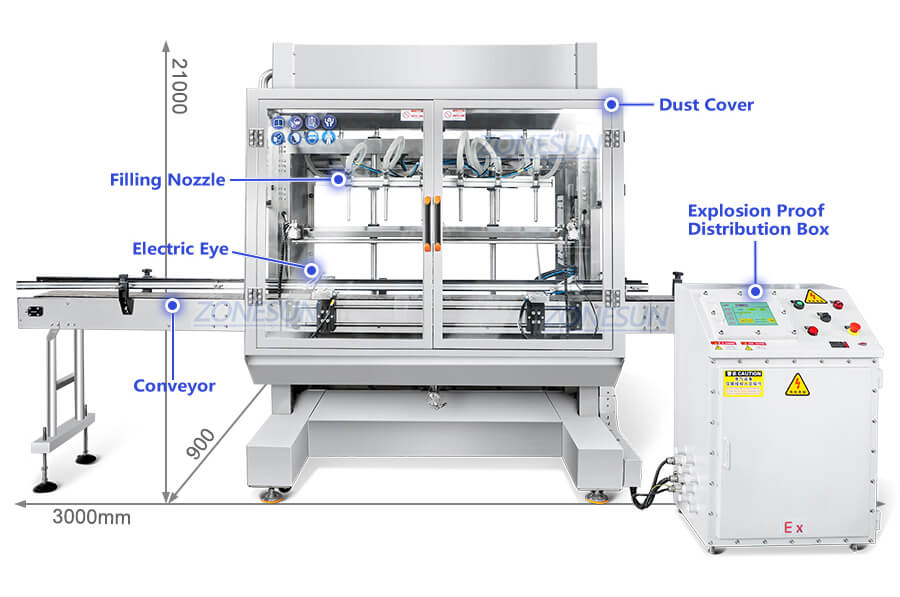

| Machine Size | About 3000*900*2100mm |

| Machine Weight | About 350kg |

| Package Size | About 840*630*1180mm+2160*1280*2250mm |

| Package Weight | About 135kg+ 562kg |

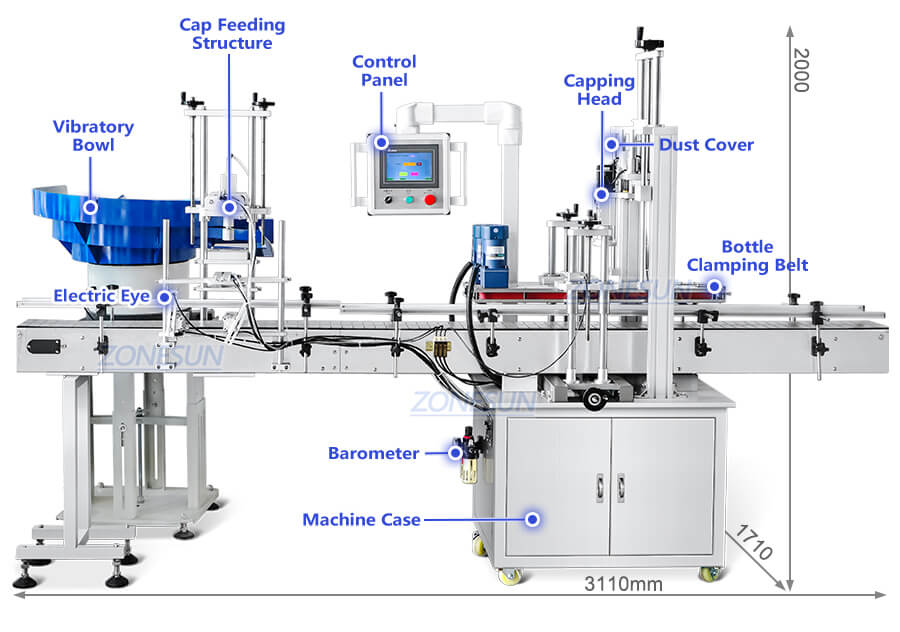

| Machine Model | ZS-XG440H |

| Voltage | AC220V/110V 50- 60HZ |

| Power | About 1100W |

| Capping Speed | About 20-60 bottles/min(depending on bottle and cap size) |

| Bottle Height | 30-300mm |

| Cap Diameter | 18-70mm |

| Bottle Diameter | 20-160mm |

| Working Pressure | 0.4-0.6MPa |

| Machine Size | About 3110*1710*2000mm |

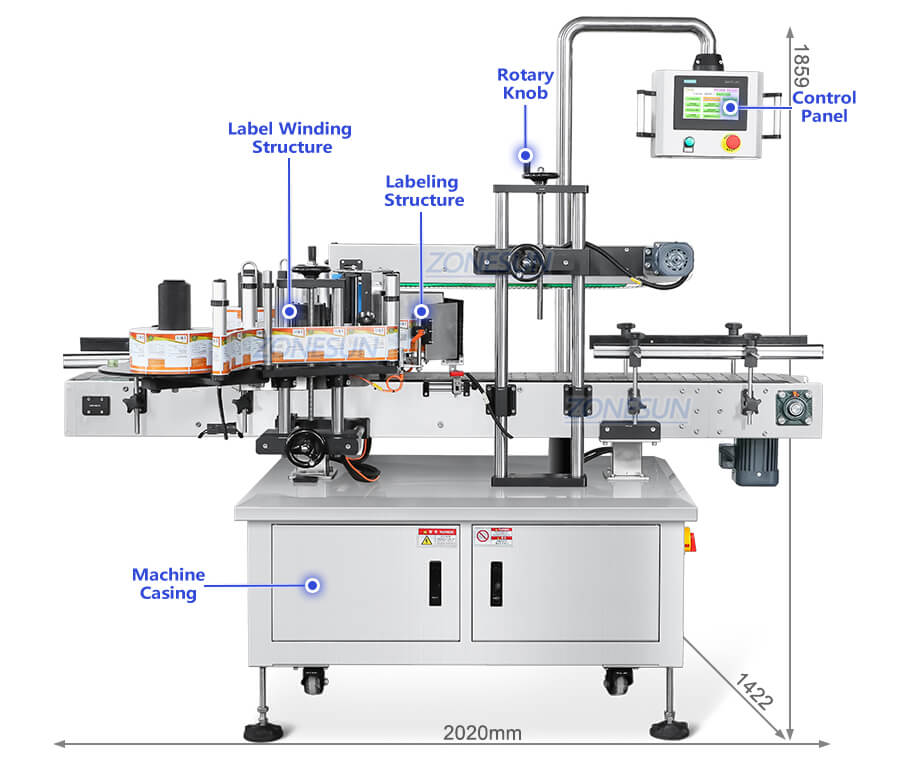

| Machine Model | ZS-TB300R |

| Voltage | 220V/110V 50-60Hz |

| Power | About 2500W |

| Labeling Speed | About 10-60 bottles/min (depending on bottle and label size) |

| Suitable Product Size | About 150-310mm(H)*150-250mm(W) |

| Label Size | 15-300mm(W)*15-200mm(H) |

| Label Roll Inner Diameter | Φ75mm |

| Label Roll Outer Diameter | Φ350mm |

| Machine Size | About 2020*1422*1859mm |

Machine Details:

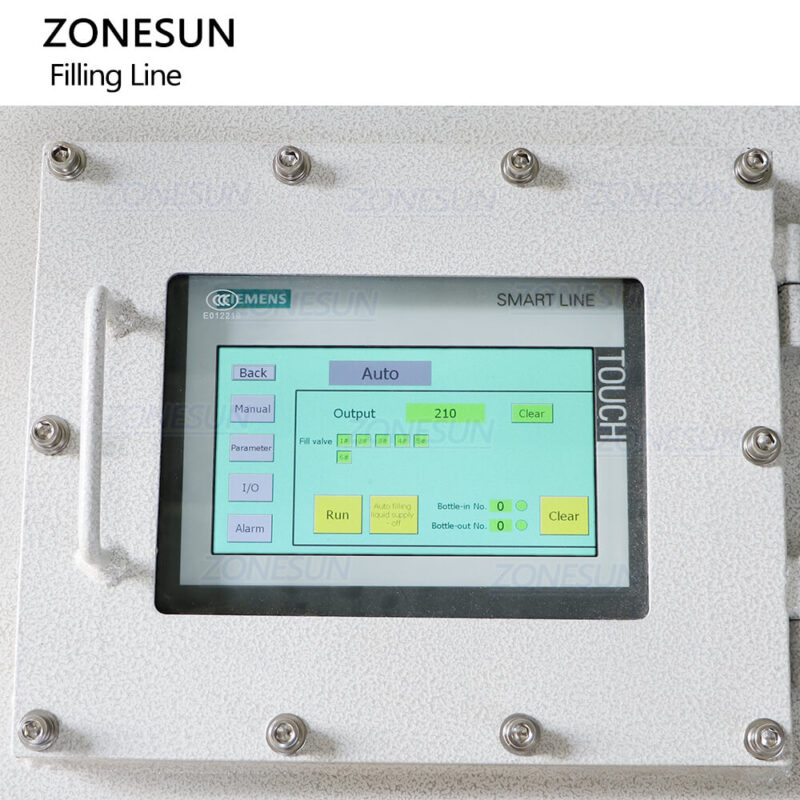

Touchscreen Panel

Intuitive panel for parameter setting. The language of panel can be customized.

6 Filling Heads

The quantity of filling heads can be customized as production need.

Vibratory Bowl

The size of vibratory bowl can be customized as your products.

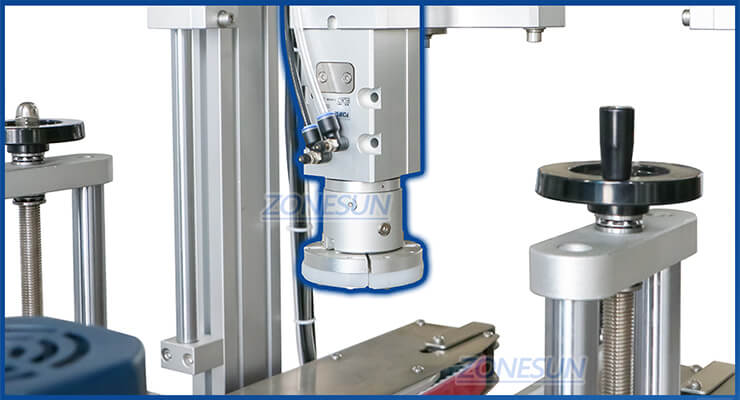

Servo Capping Structure

Servo-driven capping ensures good seal of bottle caps. The capping structure can be customized as your products.

Double Labeling Structures

Suitable for single or double-sided labeling on square bottles. Date coder can be equipped to print date.