Bottles Cap Top Side Online Print Lalebling Machine

Top-Side Real-Time Labeling Machine with Thermal Transfer Printer

Equipped with an industrial-grade thermal transfer printer for crisp, smudge-resistant labeling on bottle caps, pouches, and flat surfaces. Key features:

✅ Precision Top-Side Labeling – Ideal for curved/irregular packaging

✅ Vibratory Bowl Sorting System – Enables continuous automated feeding

✅ High-Speed Performance – Speeds up to 60 bottles/min for production lines

✅ Seamless Integration – Compatible with most automated workflows

Share to

Product Description:

Top-Side Real-Time Labeling Machine with Thermal Transfer Printer

Equipped with an industrial-grade thermal transfer printer for crisp, smudge-resistant labeling on bottle caps, pouches, and flat surfaces. Key features:

✅ Precision Top-Side Labeling – Ideal for curved/irregular packaging

✅ Vibratory Bowl Sorting System – Enables continuous automated feeding

✅ High-Speed Performance – Speeds up to 60 bottles/min for production lines

✅ Seamless Integration – Compatible with most automated workflows

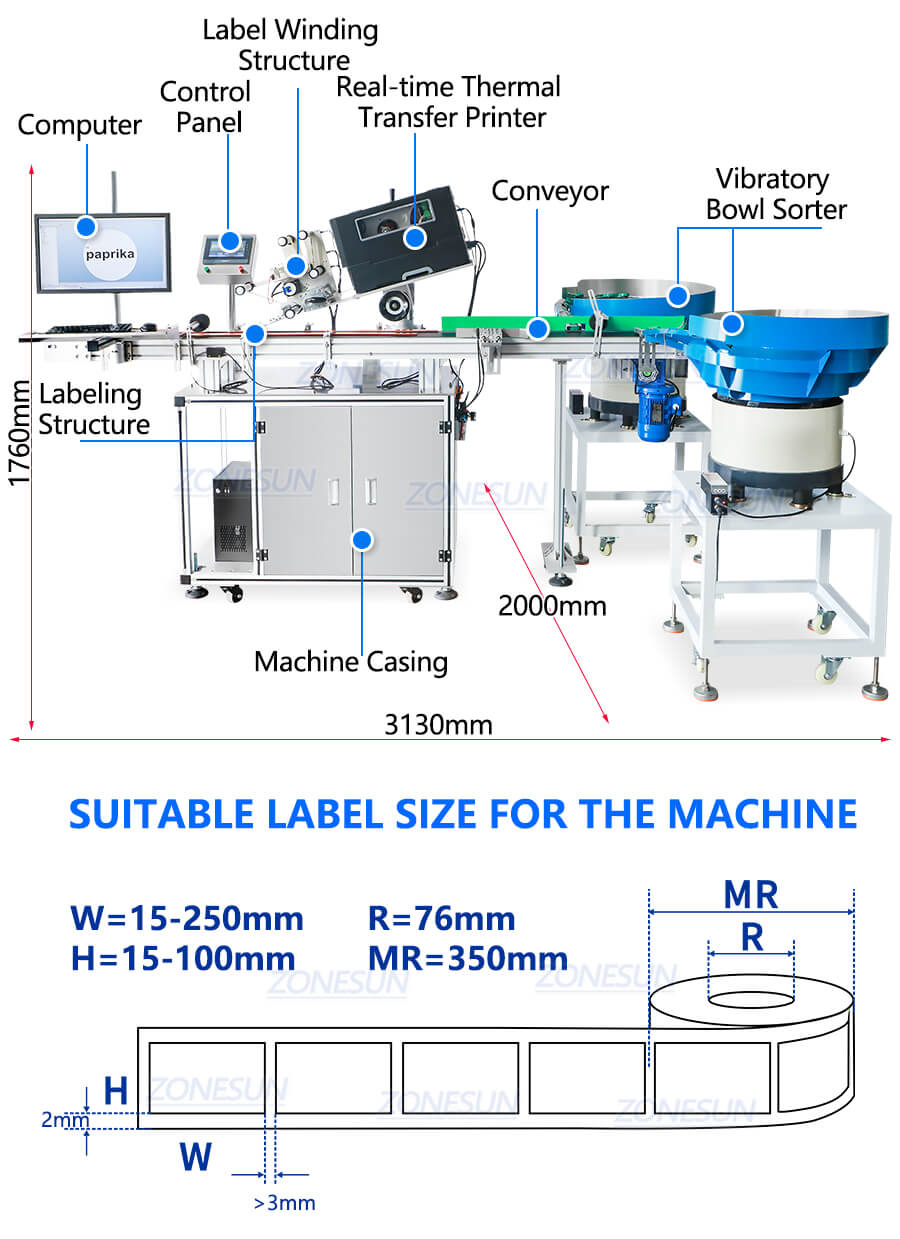

Product Parameters:

| Machine Model | ZS-TB161PO |

| Working Voltage | 110/220V 50-60HZ 1350W |

| Labeling Accuracy | ±1mm(based on label & product) |

| Working Capacity | 40-60BPM(based on label & product) |

| Suitable Product Size | 40-400mm*40-200mm*0.2-150mm(L*W*H) |

| Suitable Label Size | 15-250mm*15-100mm(W*H) |

| Machine Size | About 3130*2000*1760mm(L*W*H) |

| Machine Weight | About 180kg |

Vibrating Machine

| Machine Power | 110/220V 50-60HZ 1600*2=3200W |

| Material | Stainless Steel |

| Suitable Caps Diameter | Customized |

| Working Speed | Customized |

| Machine Size | Customized |

Product Details:

Touchscreen Control Panel

User-friendly interface for easy operation and quick parameter adjustment.

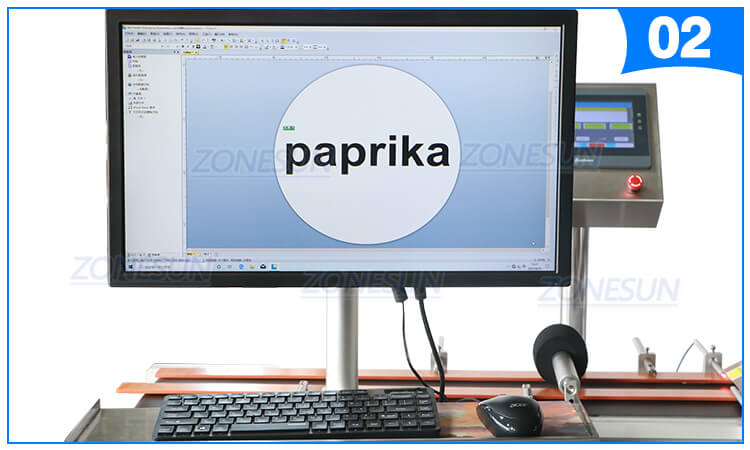

Computer Editing

Editing printed label information, such as product logos, graphics, etc., is easier through the computer

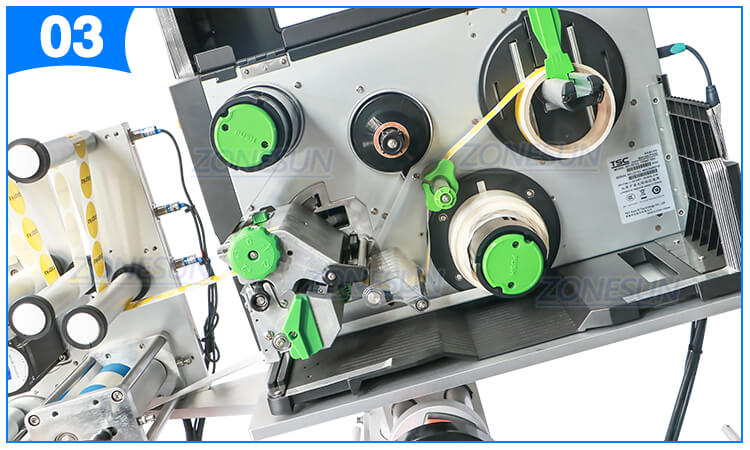

Real-Time Printer

Can be customized for ink ribbon printing or thermal transfer printing.

Vibratory Bowl Feeder

Ensures continuous and stable caps feeding for uninterrupted production.

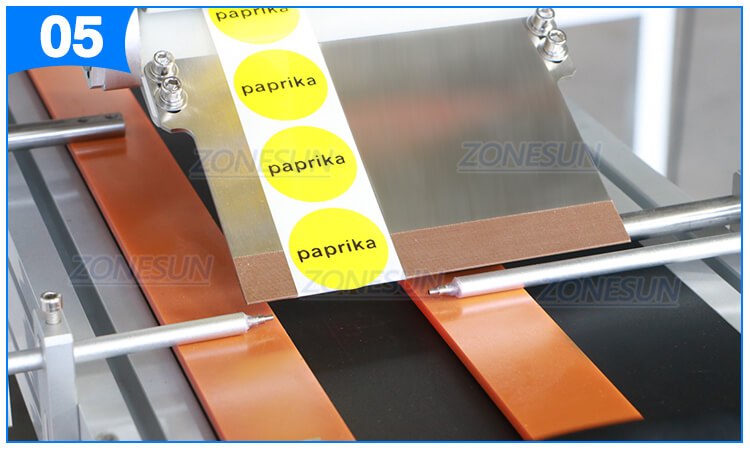

Labeling Structure

Supports flat surface labeling with an output of 40-60 bottles per minute.

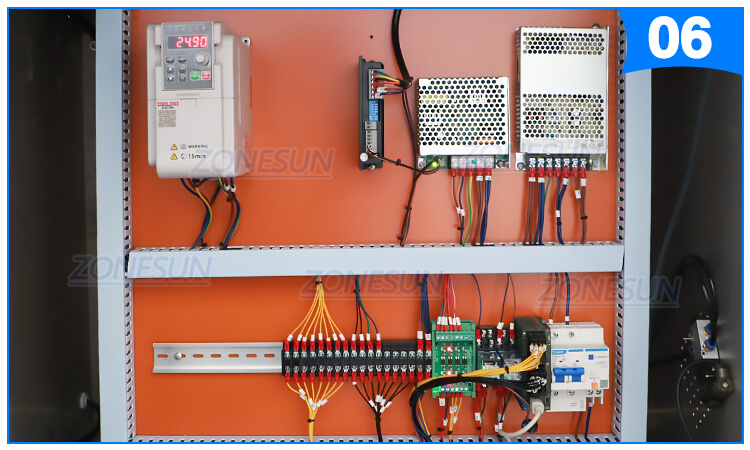

Electrical Wiring

All circuits are well-arranged for safety, reliability, and easy maintenance.