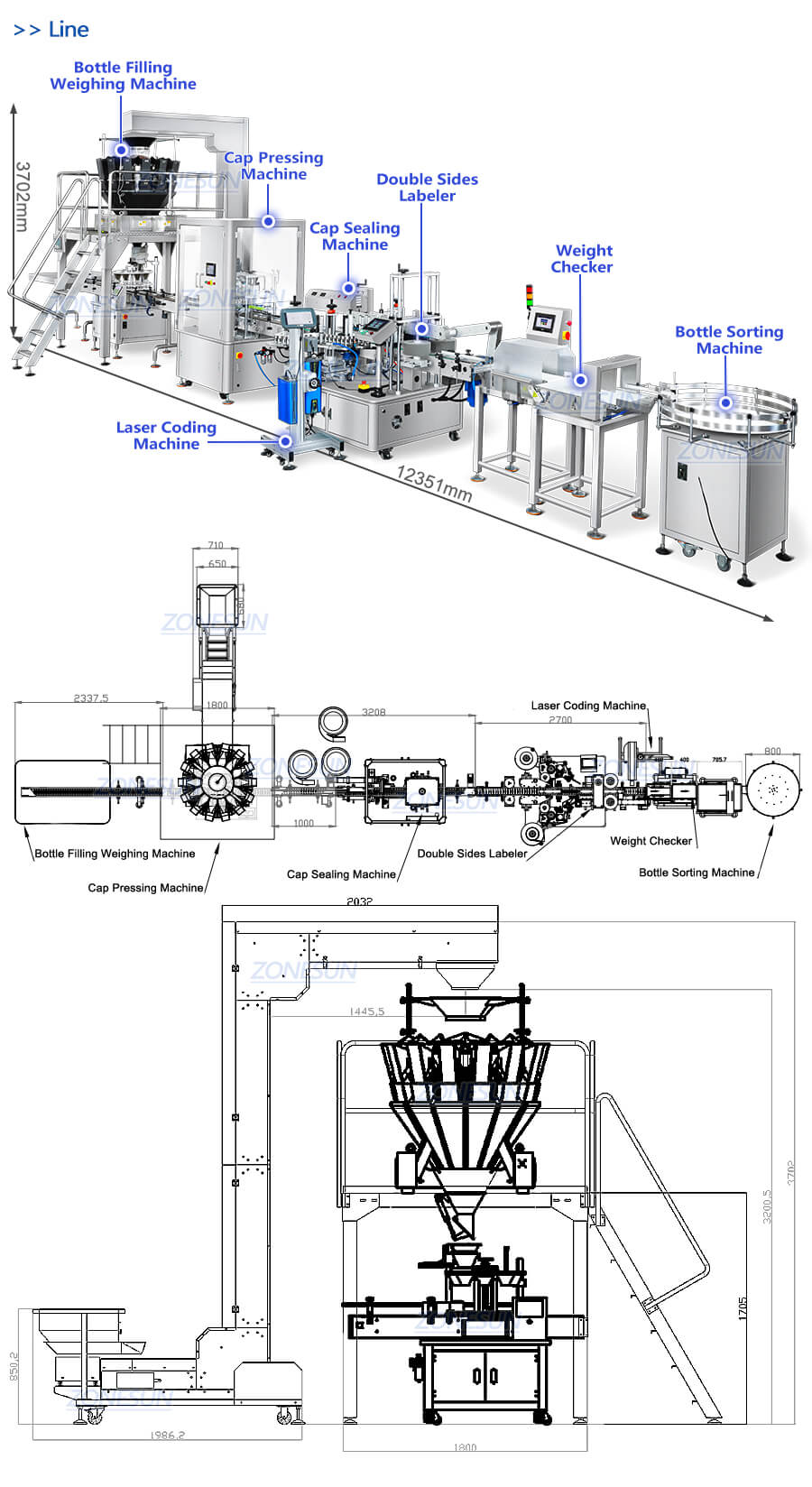

Coffer Powder Weighing Filling Line

This packing system can finish powder filling, cap pressing, sticker labeling, laser coding, and product weighing checking, it is suitable for small or medium scale production of small bottle granule products or mixture of powder and granules like coffee powder, herb seasoning etc.

Share to

Product Description:

This packing system can finish powder filling, cap pressing, sticker labeling, laser coding, and product weighing checking, it is suitable for small or medium scale production of small bottle granule products or mixture of powder and granules like coffee powder, herb seasoning etc.

Product Parameters:

Bottle Filling Weighing Machine

| Machine Model | ZS-GW14M | ||||

| Weighing Scale | Language Support | Multiple languages | |||

| Power Requirement | Single-phase AC220V/50Hz, 60Hz 2KW | ||||

| Number of Weighing Heads | 14 | ||||

| Material | 304 Stainless Steel (Mirror/Pattern Plate) | ||||

| Weighing Range | 10-1500g | 10-2000g | 10-3000g | 100-5000g | |

| Theoretical Speed | 120 b/min | 120 b/min | 120 b/min | 80 b/min | |

| Theoretica Accuracy | ±1-5g (depending on material state) | ||||

| Hopper Volume | 1.6L | 2.5L | 3L / 4L | 5L | |

| Touch Screen | 10-inch color touch screen | ||||

| Program Storage | 99 sets of data | ||||

| Packaging Dimensions (L*W*H) | 1530*1130*1310mm | 1530*1130*1310mm | 1530*1130*1300mm | 1610*1310*1600mm | |

| Machine Net Weight | 135KG | ||||

| Gross Weight | 385KG | ||||

| Rotary Powde Filling Machine | Working Capacity | 20-30 cans per minute | |||

| Power Supply | 220V 50Hz 0.3KW | ||||

| Air Pressure | 0.6 MPa | ||||

| Machine Size (L*W*H) | 2000*900 *1450 mm | ||||

| Total Weight | 200 kg | ||||

Cap Pressing Machine

| Machine model | ZS-VTYG02S |

| Machine voltage | 110/220V 50-60HZ 2KW |

| Suitable bottle size | ①83*107*170mm ②78*69*132mm ③56*67*110mm(Customizable) |

| Suitable cap size | ①83*107*27 ②78*69*24 ③56*67*19mm(Customizable) |

| Working speed | 25-30BPM |

| Working pressure | 0.4-0.6MPa |

| Machine size | About 2420*1172.5*2169mm(L*W*H) |

| Package size | About 1910*1150*2200mm(L*W*H)-Main Machine About 160*980*800(L*W*H)-Vibratory Bowl Sorter1 About 1100*900*940mm(L*W*H)-Vibratory Bowl Sorter2 |

| Package weight | About 520kg-Main Machine About 225kg-Vibratory Bowl Sorter1 About 161kg-Vibratory Bowl Sorter2 |

Cap Sealing Machine

| Machine model | ZS-FK4200V |

| Power supply | 220V 50HZ 4200W |

| Sealing diameter | 15-60mm/20-70mm/35-85mm/50-120mm/60-130mm |

| Sealing speed | 0-260bottles/min(based on bottle size) |

| Suitable bottle height | 10-300mm(based on 900mm height conveyor belt) |

| Machine size | About 700*690*1450mm |

| Machine weight | About 43kg |

| Package size | About 850*650*1590mm |

| Package weight | About 92kg |

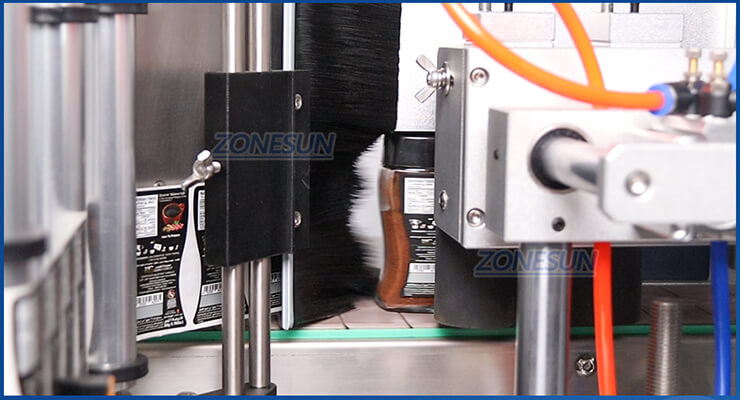

Double Sides Labeler

| Machine model | ZS-TB600 |

| Flat Bottle | Single/Double Side |

| Power Supply | AC220V 50Hz/60Hz 1500W |

| Labeling Capacity | 60-350 bottles /min(depends on bottle size) |

| Labeling Material Thickness | 20-120mm |

| Labeling Material Height | 30-350mm |

| Label Size | (L)25-300mm (H)15- 200mm |

| Roll Inside | φ76mm |

| Roll Outside Diameter(mm) | φ350mm |

| Machine Size | About 2120*940*1500mm |

| Packing Size | About 2850*1300*1900mm |

| Net Weight/Gross Weight | About 450KG/650kg |

Laser Coding Machine

| Machine model | ZS-LM1 |

| Power Supply | 110/220V 50-60Hz 30W |

| Cooling Method | Air cooling |

| Laser | CO2 |

| Port | SD card, USB 2.0, RS232 |

| Wave Length | 9.3/10.2/10.6 um |

| Working Capacity | PVC tubes: 40 m/min PET bottles: 20000 bottles/h Coated cartons: 35 m/min |

| Marking Range | 70*70/90*90/110*110/140*140mm |

| Applications | PET/Acrylic/Glass/Leather/Plastic/Cloth/Rubber(HDPE is not suitable) |

| Language | English, French, Korean, Japanese, Russian, Arabic, etc. |

| Machine Weight | About 110kg |

| Machine Size | About 1430*565*930mm |

Weight Checker

| Machine model | ZS-MD210 |

| Power supply | AC220V±10% 50HZ (60HZ) |

| Rated power | 0.15KW |

| Single weighing range | 1500g |

| Weighing accuracy range | ±0.2g-±0.5g |

| Minimum scale | 0.1g |

| Conveying speed | 30~-100m/min |

| Maximum speed | 160pc.s/min |

| Weighed material size | 300mm (L)*200mm (W) |

| Weighing platform conveyor belt size | 400mm (L)*210mm (W) |

| Product size | 1522mm(L)*560mm (W)*1222mm(H) |

| Rejection method | Push rod type/lever/flip plate/blowing type/belt sinking |

| Control system | high-speed A/D sampling controller |

| External air source | 0.6-1Mpa |

| Air pressure interface | 8mm |

| Body material | SUS304 stainless steel |

Bottle Sorting Machine

| Machine Model | ZS-SP800S |

| Voltage | 220V 50Hz (110V can be customized) |

| Power Supply | 200W |

| Bottle Specifications | Square bottle / Round bottle |

| Conveying Speed | 0-20 revolutions per minute (adjustable) |

| Turntable Diameter | 800 mm |

| Dimensions (L×W×H) | About 550×550×990 mm |

| Package Size (L×W×H) | About 1050×1000×1130 mm |

| Net Weight / Gross Weight | About 93 kg / 120 kg |

Product Details:

Control Panel

Whole production line is equipped with intuitive human-machine interface for easy control.

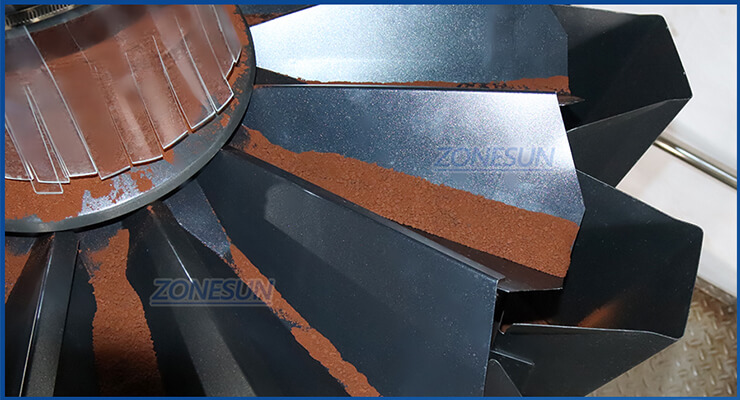

14 Weighing Heads

Quantity of weighing heads is customizable, suitable for granular and powder mixtures like coffee powder, spices.

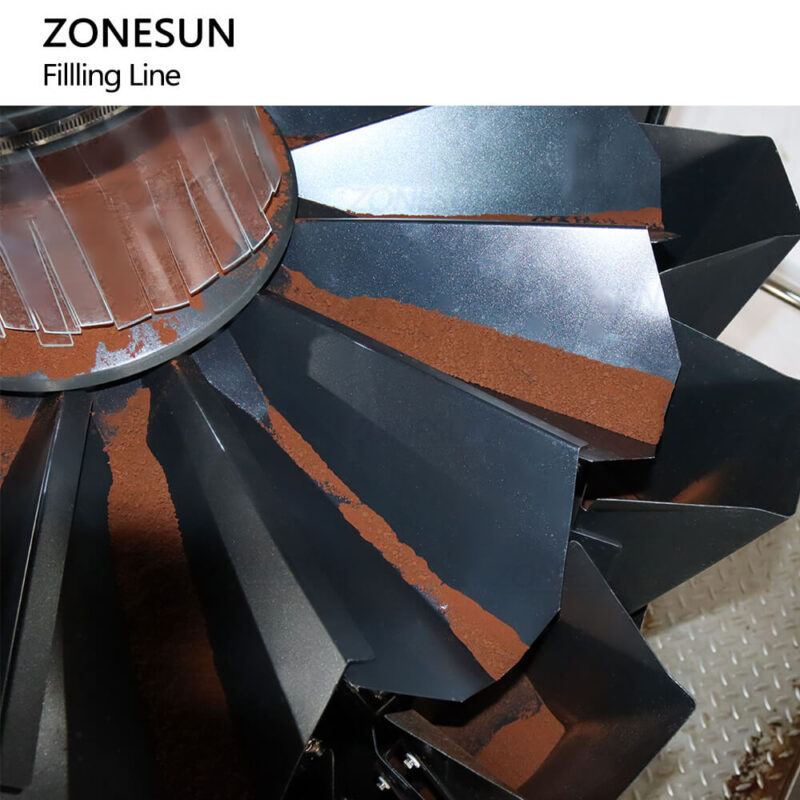

Rotary Filling

Uses starwheel to ensure continuous filling with smooth operation.

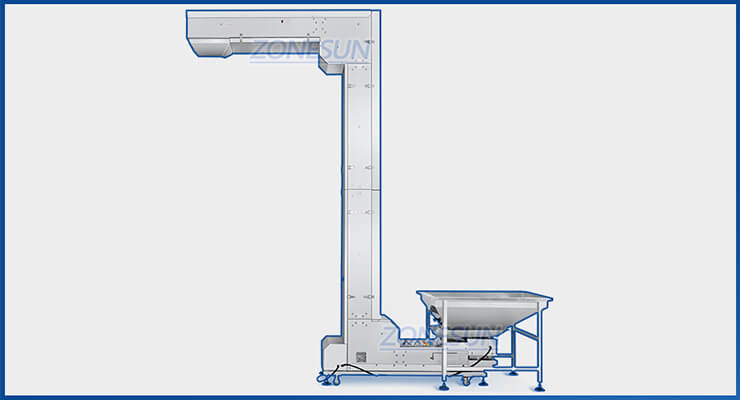

Z-Type Elevator Feeding

Efficiently transports filling material to the machine.

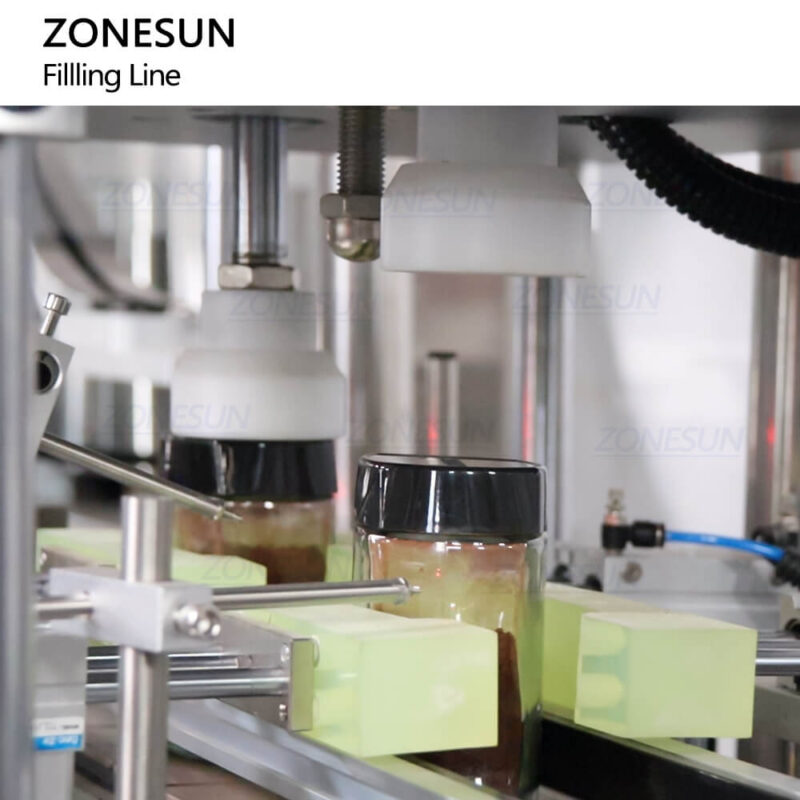

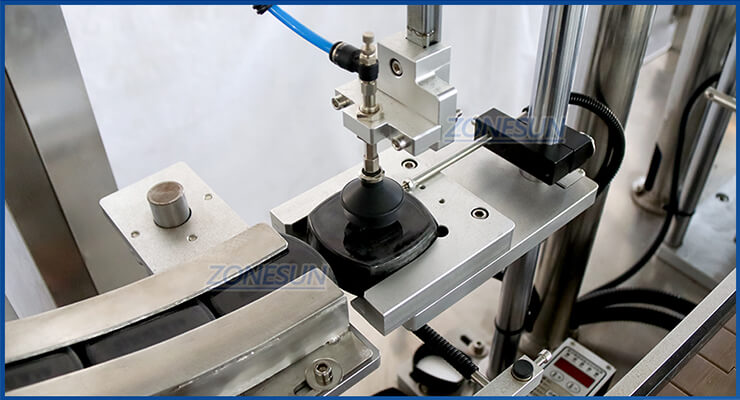

Cap Passing

Using suction cups, it accurately picks and places caps onto bottles.

Cap Pressing Structure

Double pressing heads, it can reach 30 bottles/min, working height is adjustable.

Laser Coding Function

Marks production dates or logos on labels or bottles.

Double Sides Labeling

Labeler is customizable for single side, double sides or wrap-around labeling.

Weigh Checker

Automatically rejects non-compliant products.

Bottle Outfeed Turntable

Size of turntable machine is customizable based on production, saves working labor.