Corrosive Liquid Filling Capping Machine

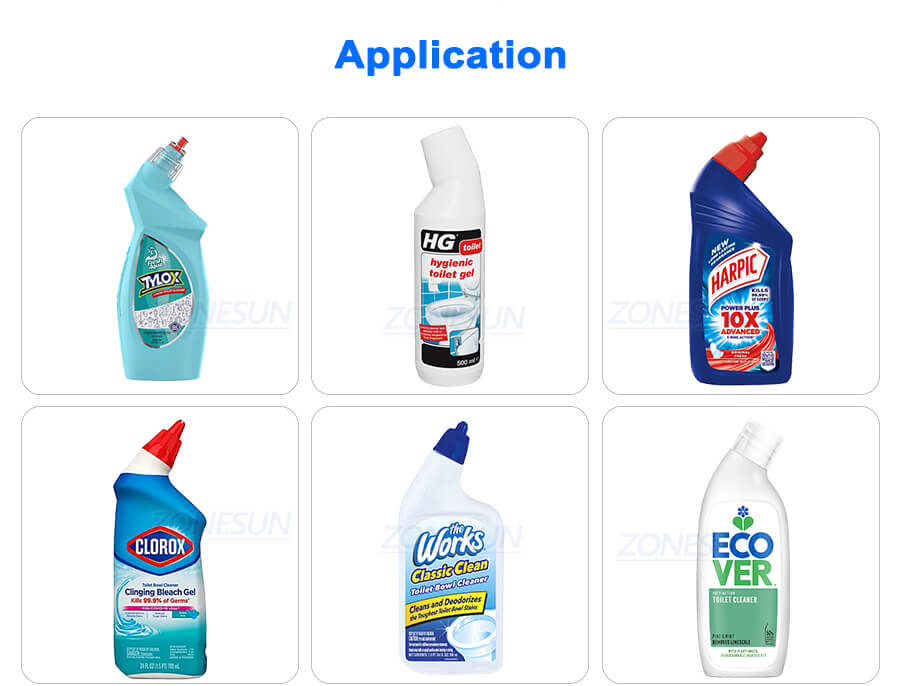

This packaging system is consist of 16 heads liquid filling machine and angle neck bottle capping machine, it is designed for packaging corrosive liquid like toilet cleaner. This packaging system can reach 3000BPH, suits small & medium scale production.

Share to

Product Description:

This packaging system is consist of 16 heads liquid filling machine and angle neck bottle capping machine, it is designed for packaging corrosive liquid like toilet cleaner. This packaging system can reach 3000BPH, suits small & medium scale production.

Product Parameters:

| Machine model | ZS-YTCR16C |

| Machine voltage | 220/380V 50-60HZ 2.4KW |

| Filling volume | 10ml-5L(customizable) |

| Suitable bottle size | Customizable |

| Suitable bottle neck | φ30mm+ |

| Filling nozzle quantity | 4/6/8/10/12/14/16(customizable) |

| Working capacity | 3200BPH(based on 500ml) |

| Filling accuracy | ±0.3% |

| Machine main material | PP |

| Air pressure | 0.6-0.8MPa |

| Machine size | About 2100*1100*800mm |

| Machine weight | About 800kg |

| Machine model | ZS-XG25V |

| Machine voltage | 220/380V 50-60HZ 2.4KW |

| Suitable bottle size | customizable |

| Working capacity | 50-80BPM |

| Suitable bottle neck | φ30mm+ |

| Machine main material | PP |

| Air pressure | 0.6-0.8MPa |

| Machine size | About 1700*1300*1650mm |

| Machine weight | About 500kg |

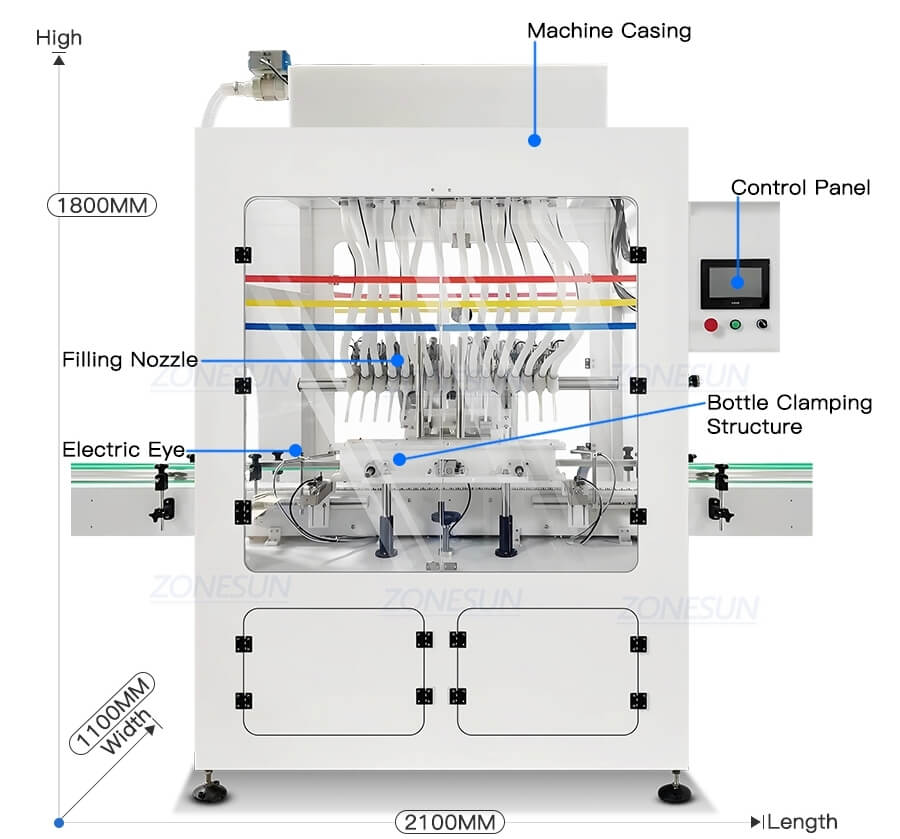

Product Details:

Control Panel

Makes parameter setting more intuitively, simplifies machine operation and debugging.

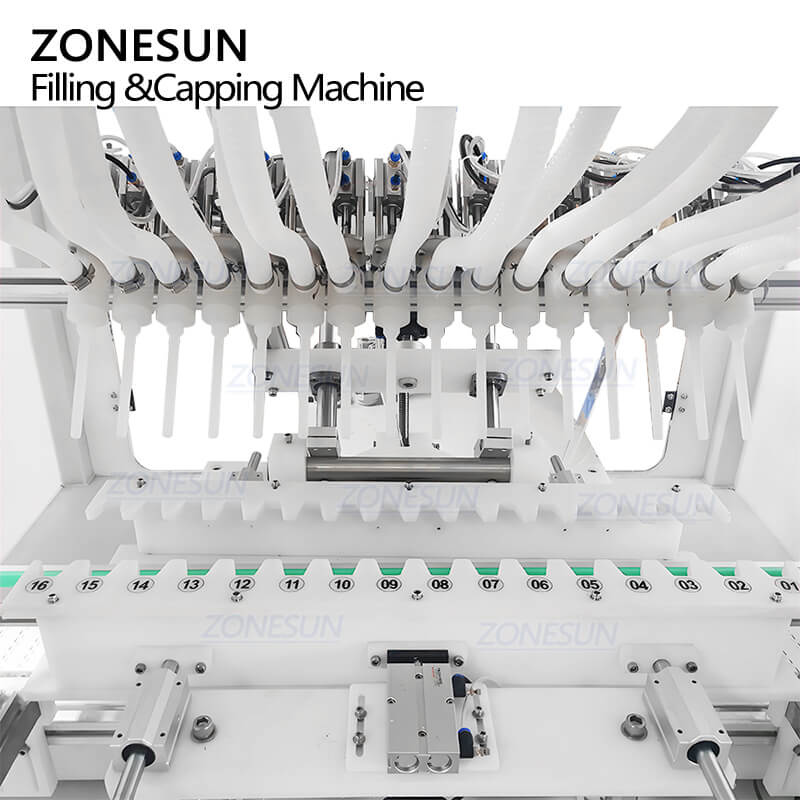

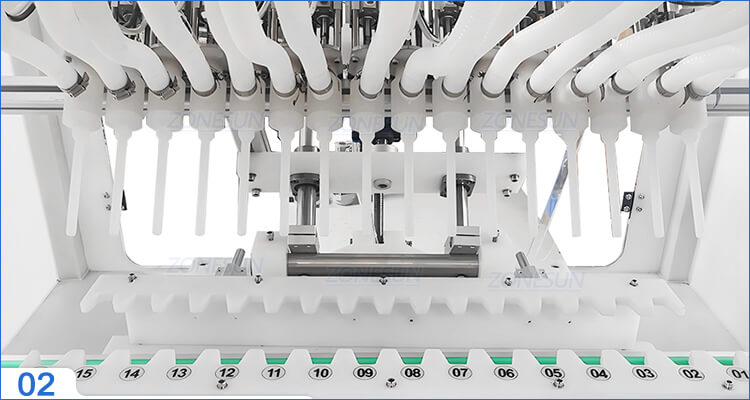

Filling Nozzles

Designed for angle neck bottles, ensures smooth filling. Quantity of filling nozzles is customizable.

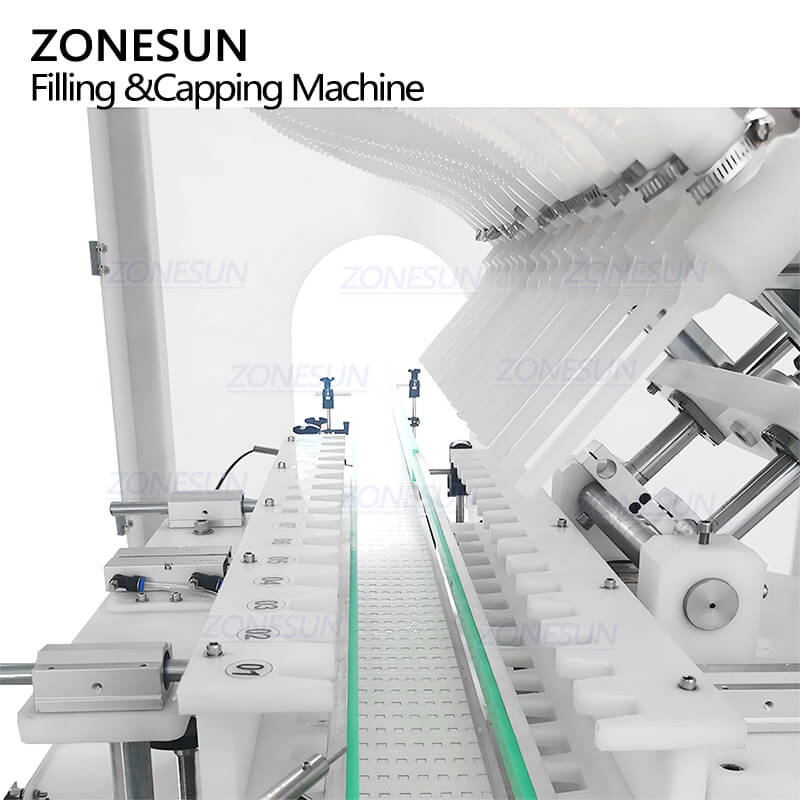

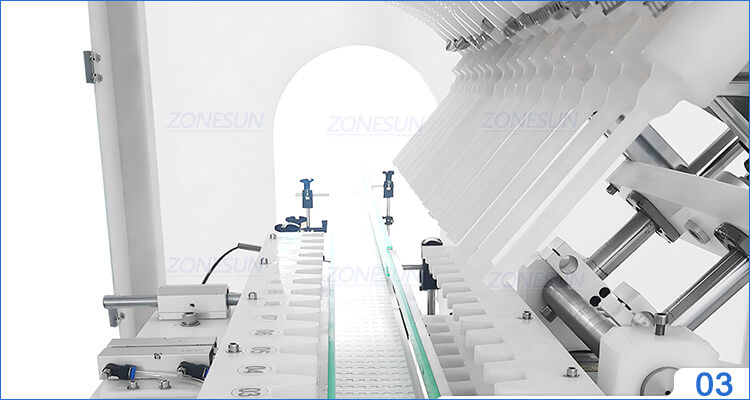

Anti-corrosive Chain Conveyor

Conveyor is made of PP material to ensure safety operation.Length and width is customizable as production need.

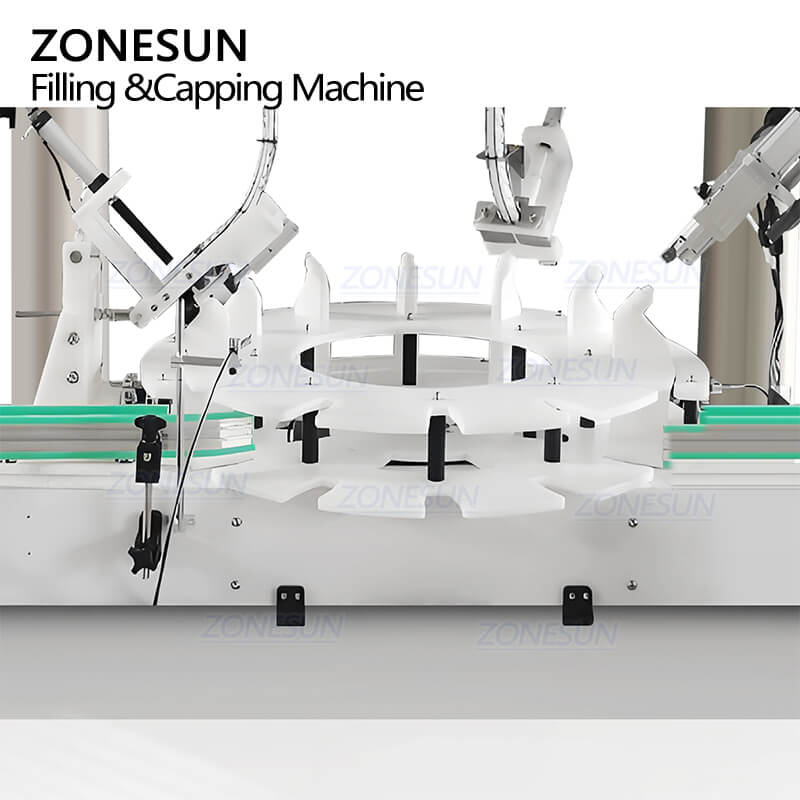

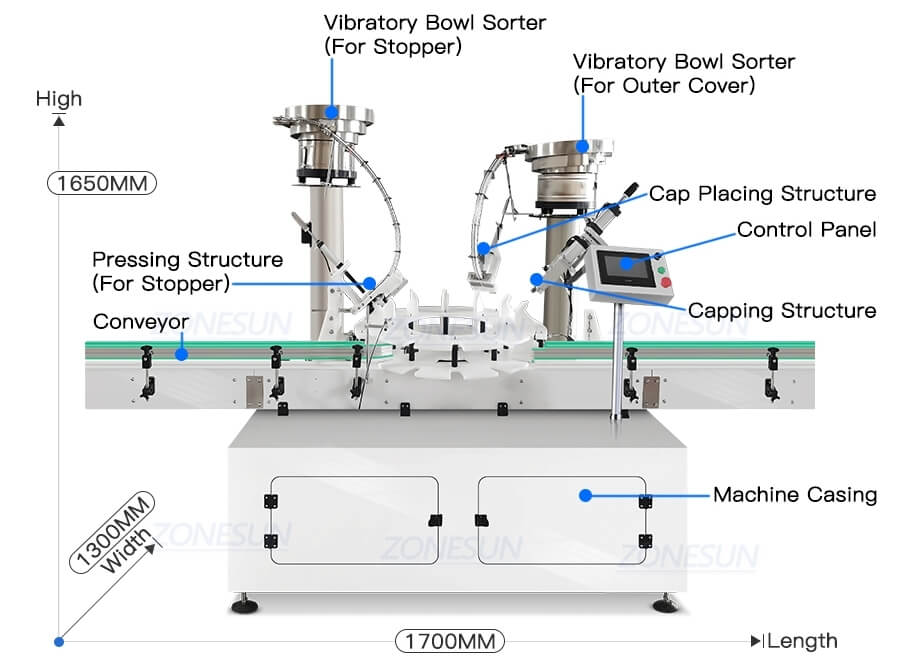

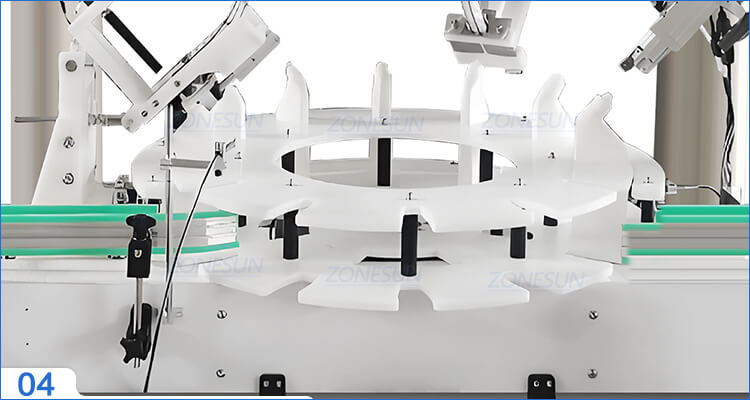

Starwheel

Stopper pressing, cap placing & screwing are finished through starwheel, compact machine body and has high working accuracy.