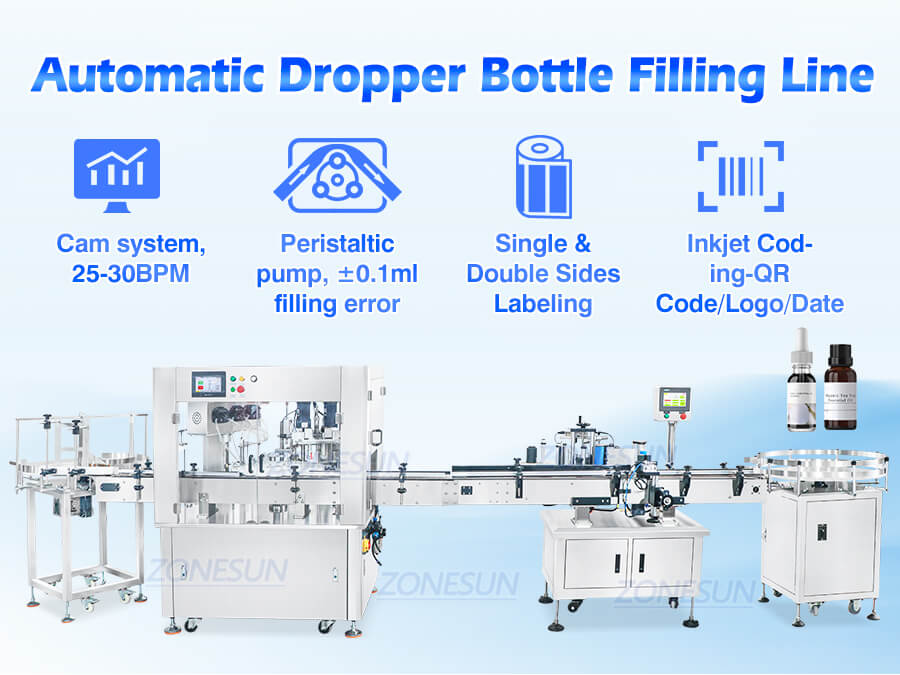

Cosmetic Essential Oil Filling Line

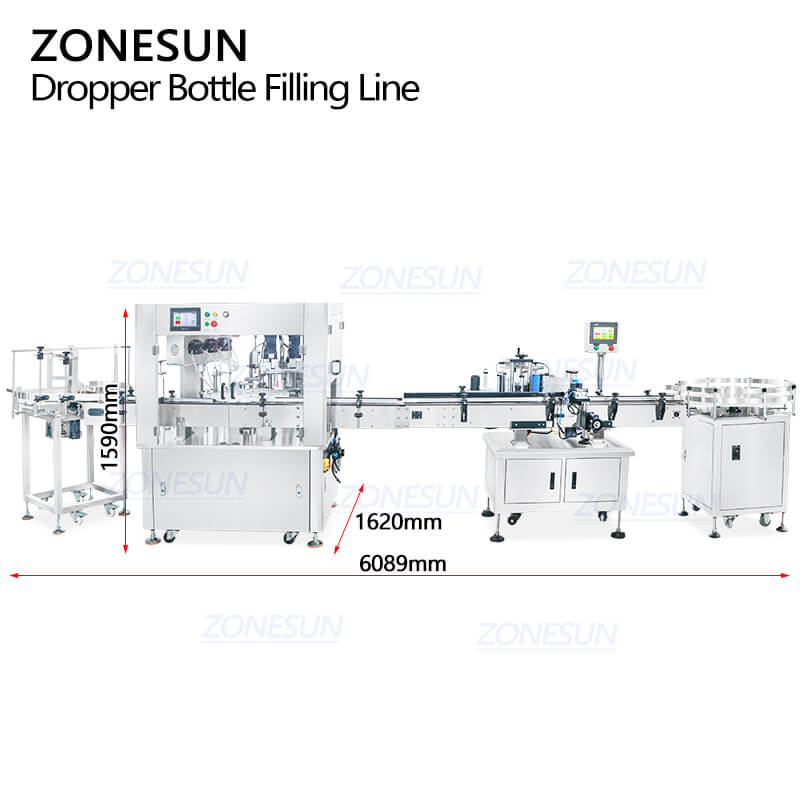

This filling system is used for packaging small bottles like cosmetic serum, essential oil, massage oil etc.It includes monoblock filling capping machine, labeling machine(with date coder) and bottle sorting machine. It suits small scale production.

Share to

Product Description:

This filling system is used for packaging small bottles like cosmetic serum, essential oil, massage oil etc.It includes monoblock filling capping machine, labeling machine(with date coder) and bottle sorting machine. It suits small scale production.

Product Parameter:

| Machine model | ZS-LP800N |

| Power supply | 220V/110V 50-60Hz 200W |

| Turntable diameter | 800mm |

| Suitable bottle diameter | 20-100mm |

| Suitable bottle height | 32-320mm |

| Working speed | 40-60 bottles/min(depending on bottle size) |

| Package size | About 1230*1010*1260mm |

| gross weight | About 141kg |

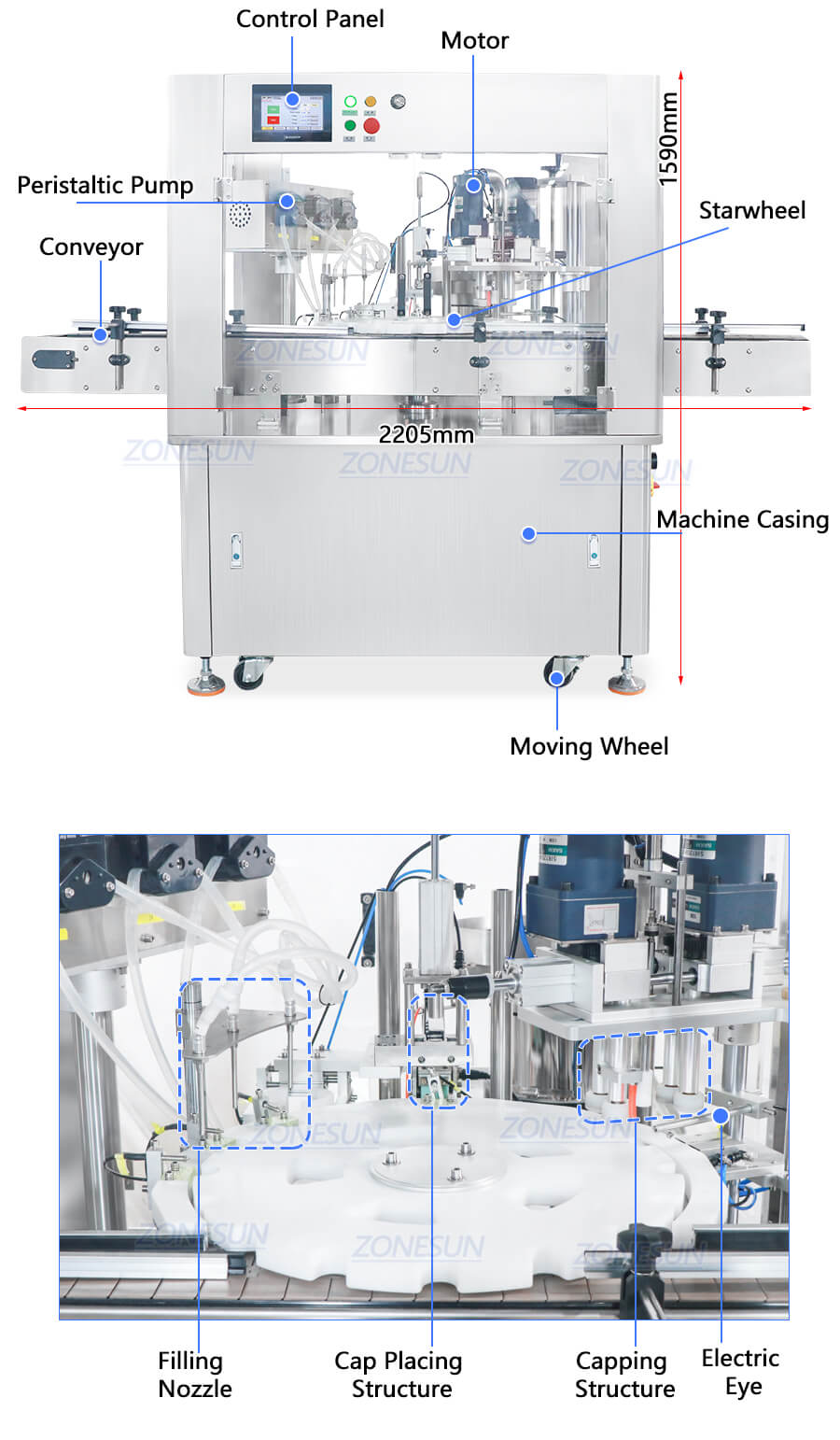

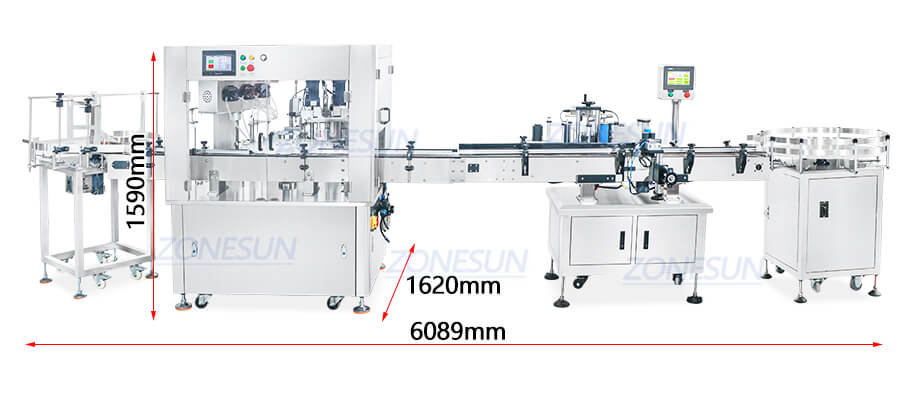

| Machine model | ZS-AFC45 |

| Machine voltage | 110/220V 50-60HZ 2.5KW |

| Filling pump | Peristaltic Pump |

| Filling range | 10-100ml |

| Filling error | ±0.1ml |

| Working capacity | 25-30BPM |

| Suitable bottle size | 20-50mm*50-110mm(φ*H) |

| Suitable cap size | Φ=21.5mm (Customizable) |

| Air pressure | 0.4-0.6MPa |

| Machine size | About 2205*1620*1590mm(L*W*H) |

| Machine weight | About 700kg |

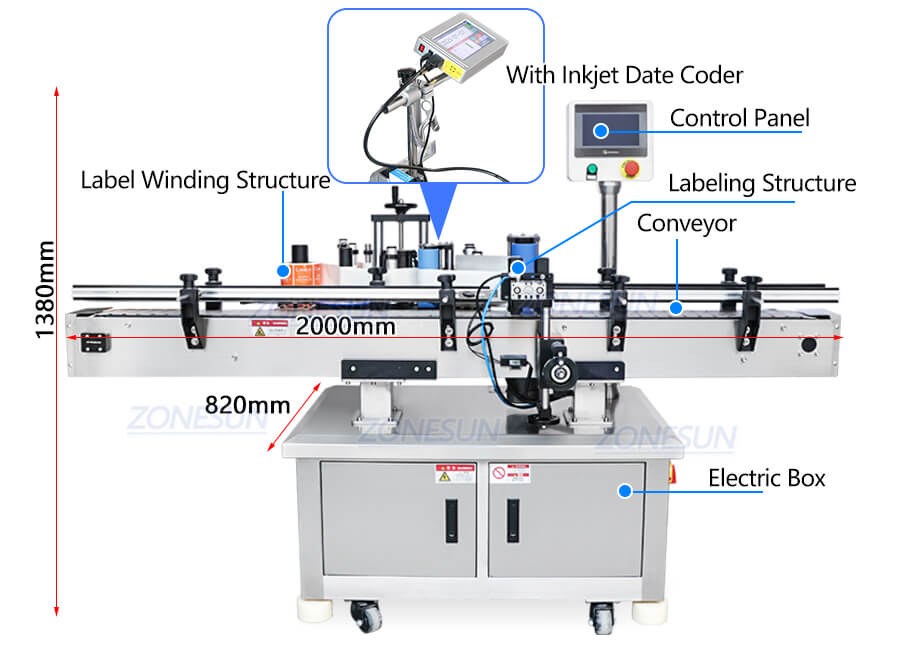

| Model | ZS-TB260R |

| Power supply | AC 220 V 50/60 Hz 1 KW |

| Labeling capacity(bottles/min) | 25-50 bottles/min(depends on bottle size) |

| Labeling accuracy(mm) | ± 1.0 mm |

| Suitable Bottle Diameter | Φ30-100 mm H=30-200 mm |

| Label size(mm) | (L)20-300 mm (H)12-130 mm |

| Roll inside diameter(mm) | Φ76 mm |

| Roll outside diameter(mm) | Φ350 mm |

| Conveyor Size | 112*2000 mm(W) |

| Machine size | About 2000*820*1380mm |

| Machine weight | About 180 kg |

| Packing Size | About 2100*890*1520mm |

| Package weight | About 250 kg |

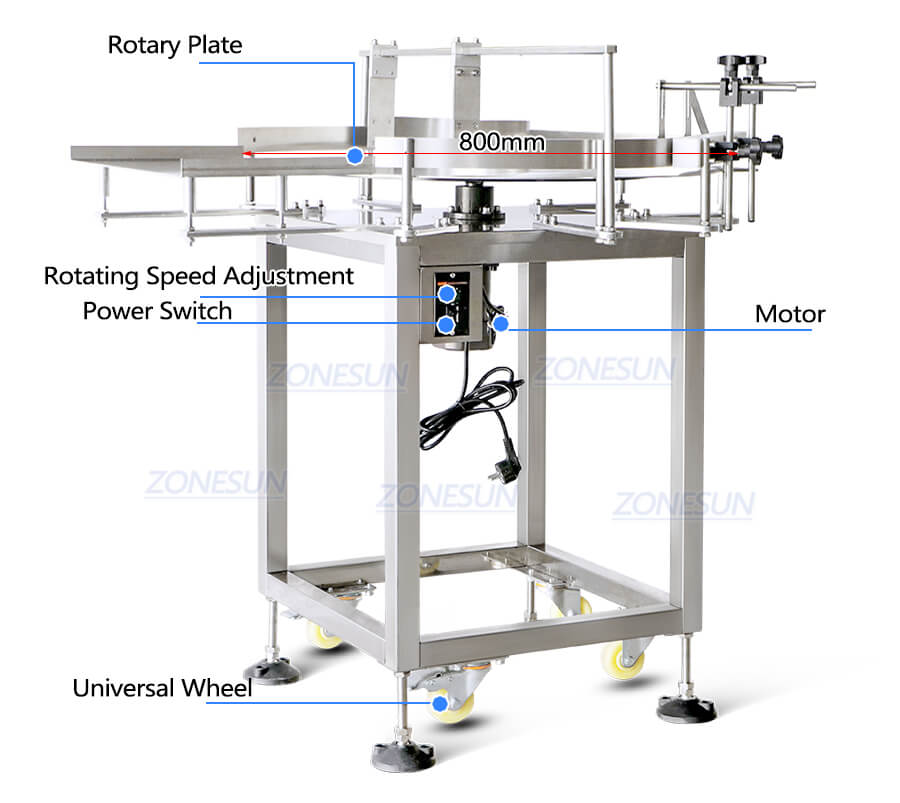

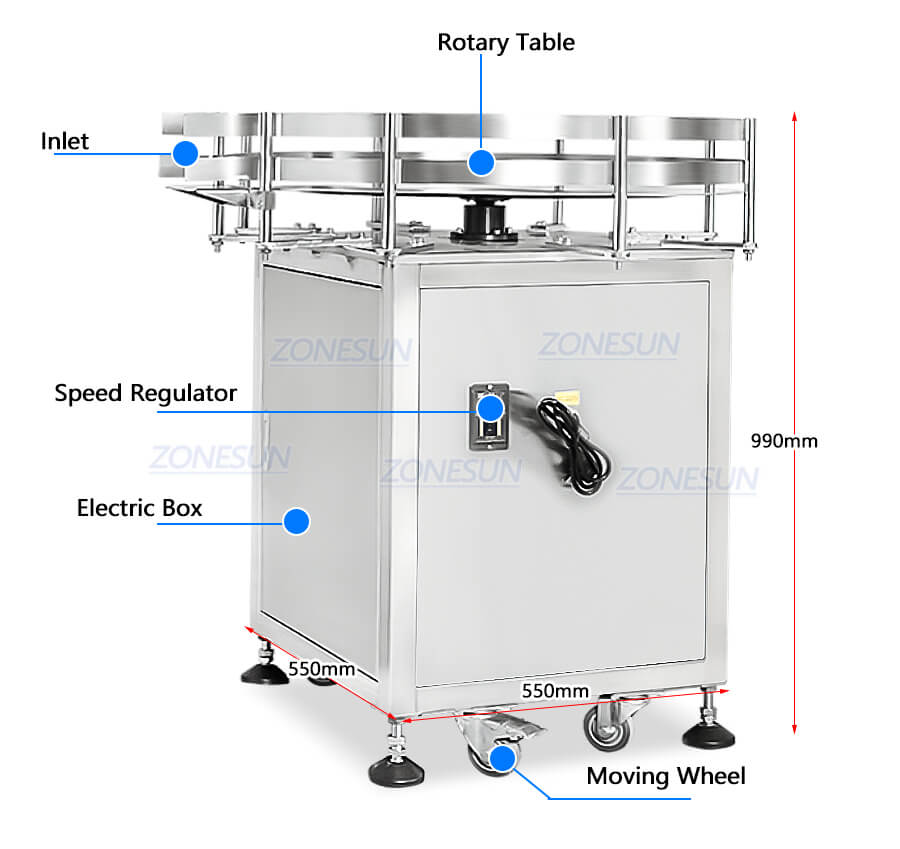

| Machine model | ZS-SP800S |

| Bottle specifications | Square bottle/round bottle |

| Conveying speed | 0-20 revolutions per minute(adjustable) |

| Voltage | 220V 50Hz (110V can be customized) |

| Power supply | 200W |

| Turntable diameter | 800 mm Available |

| Dimensions | About 550*550*990mm |

| Package size | About 1050*1000*1130mm |

| Net weight/Gross weight | About 93kg/120kg |

Product Details:

Touch Screen Control Panel

Parameter setting will be more convenient, multi kinds of language are customizable as production needs.

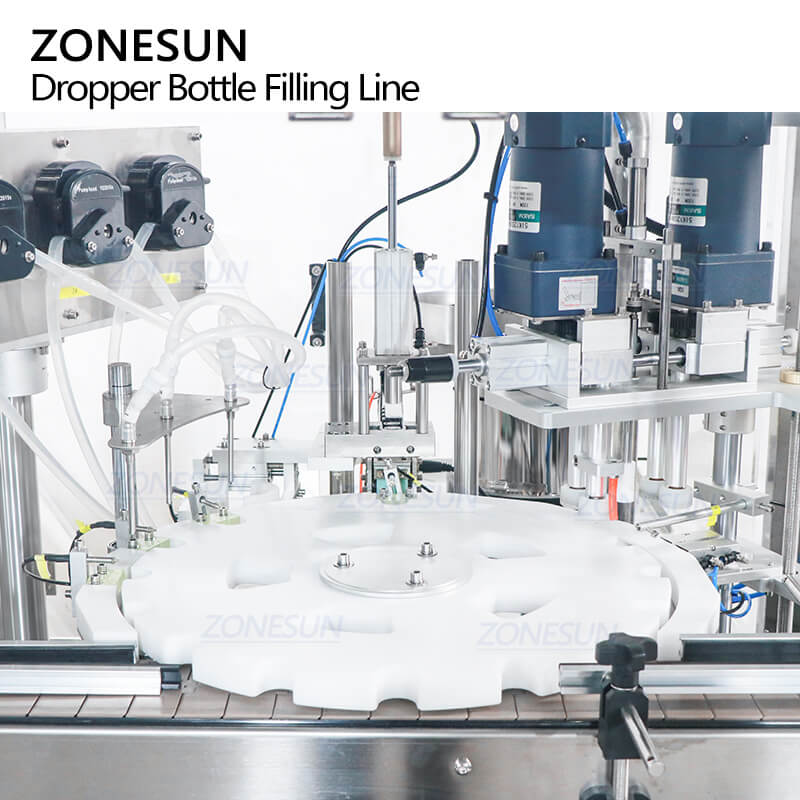

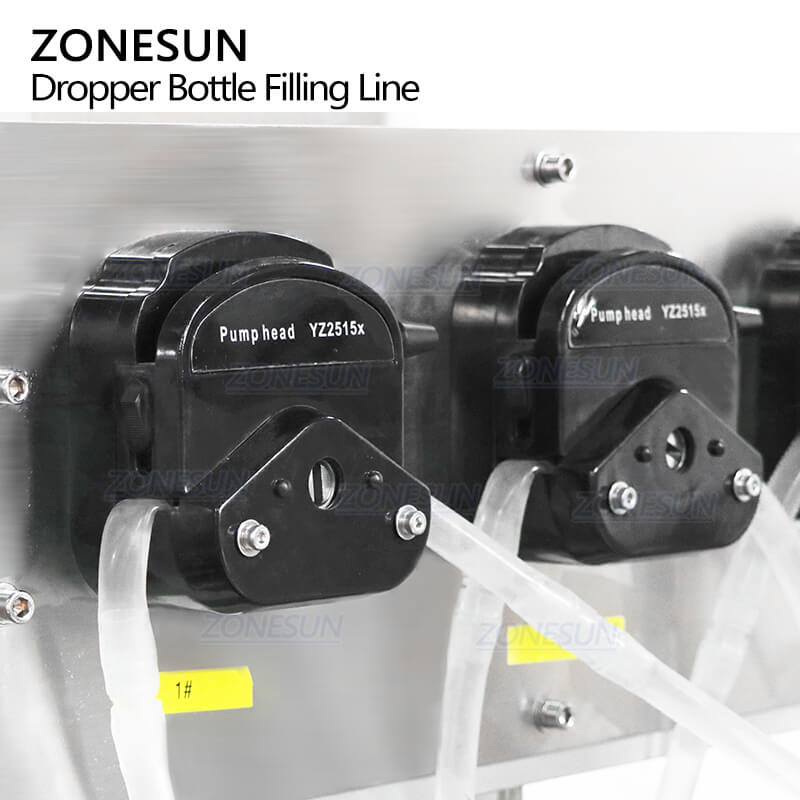

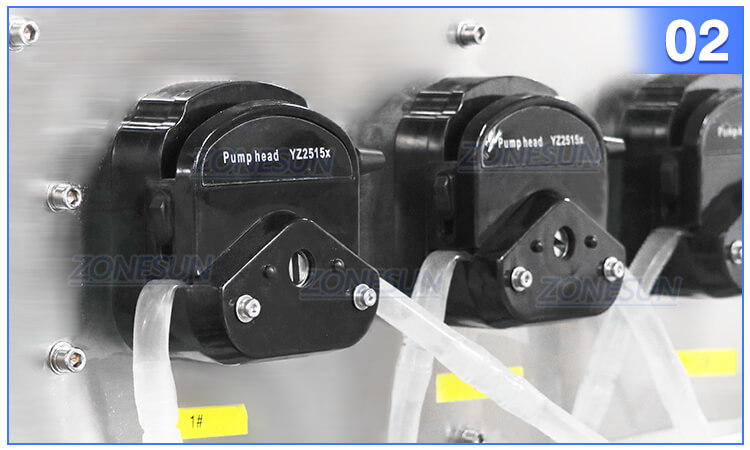

Peristaltic Pump

Liquid only pass through filling hose, it has high filling accuracy and high packaging quality.

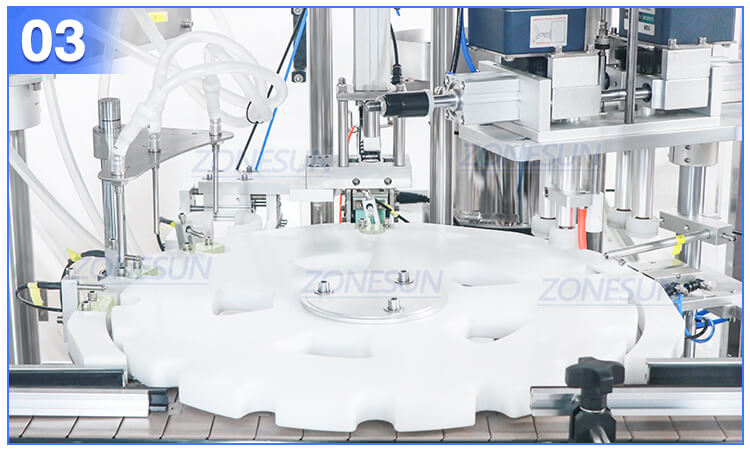

Monoblock Design

Filling, capping placing and capping work are controlled by cam system, it can reach 25-30BPM.

Vibratory Bowl Sorter

This is customizable as cap size, it can supply caps in time to ensure smooth working.

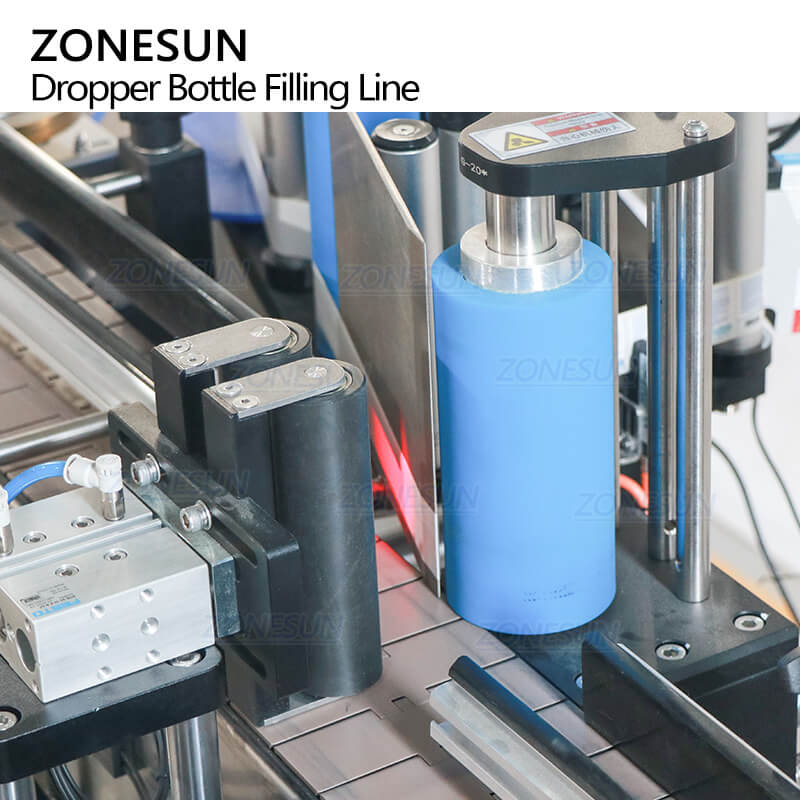

Labeling Structure

Using three-roller labeling structure, it is suitable for single and double sides labeling for round bottles.

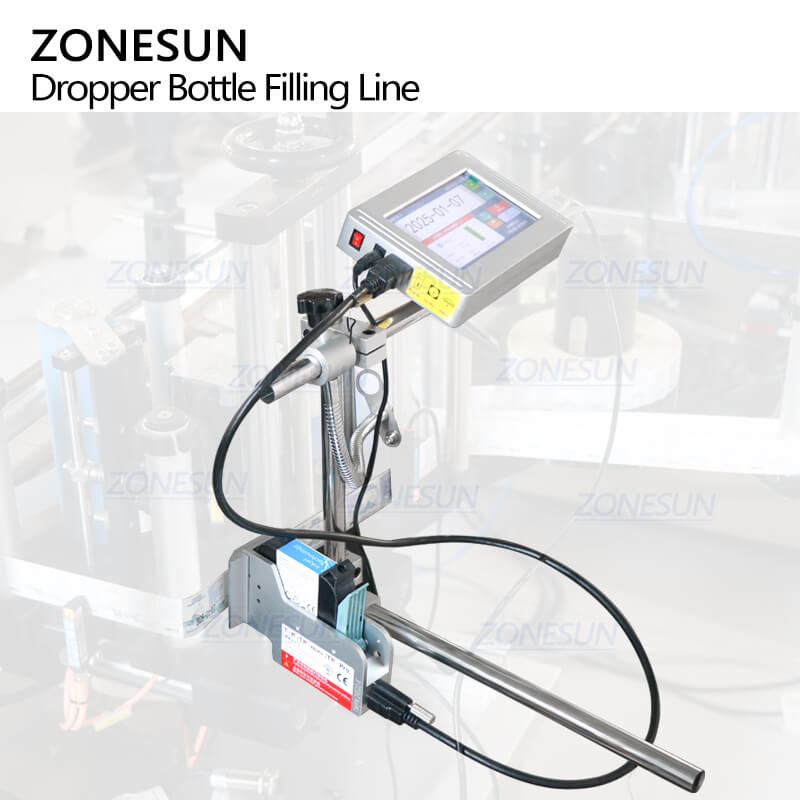

Inkjet Coder

It is suitable for print batch number, production date, QR code on stickers during labeling work.

Bottle Turntable

Size of turntable machine is customizable based on production, saves working labor.