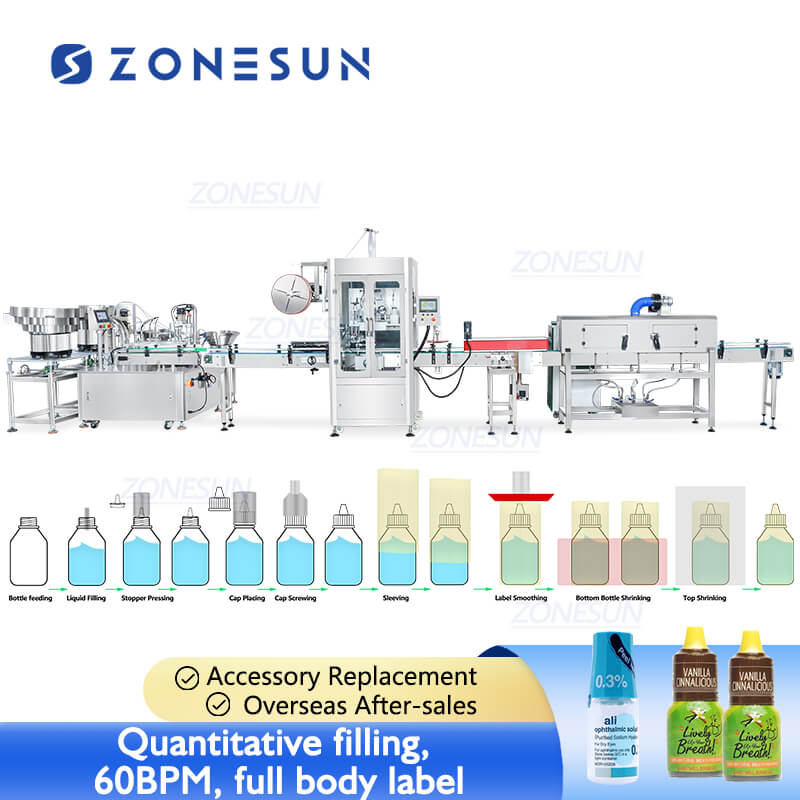

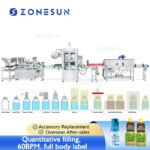

Irregular Bottle Filling Capping Shrink Sleeve Labeling Machine

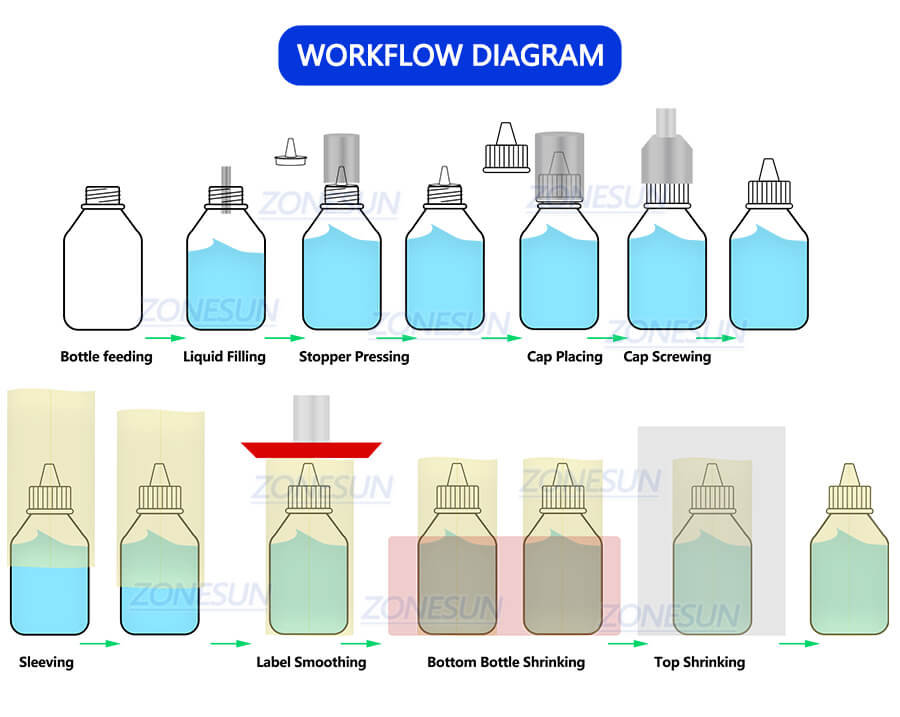

This packaging system is designed for small irregular bottle packaging like Biological extract, eyedrops.It can feed bottle, fill liquid, press stopper, tighten outer cover and shrink packaging film at the same time.Working capacity can reach 40-60BPM.

Share to

Product Description:

This packaging system is designed for small irregular bottle packaging like Biological extract, eyedrops. It can feed bottle, fill liquid, press stopper, tighten outer cover and shrink packaging film at the same time.Working capacity can reach 40-60BPM.

Product Parameters:

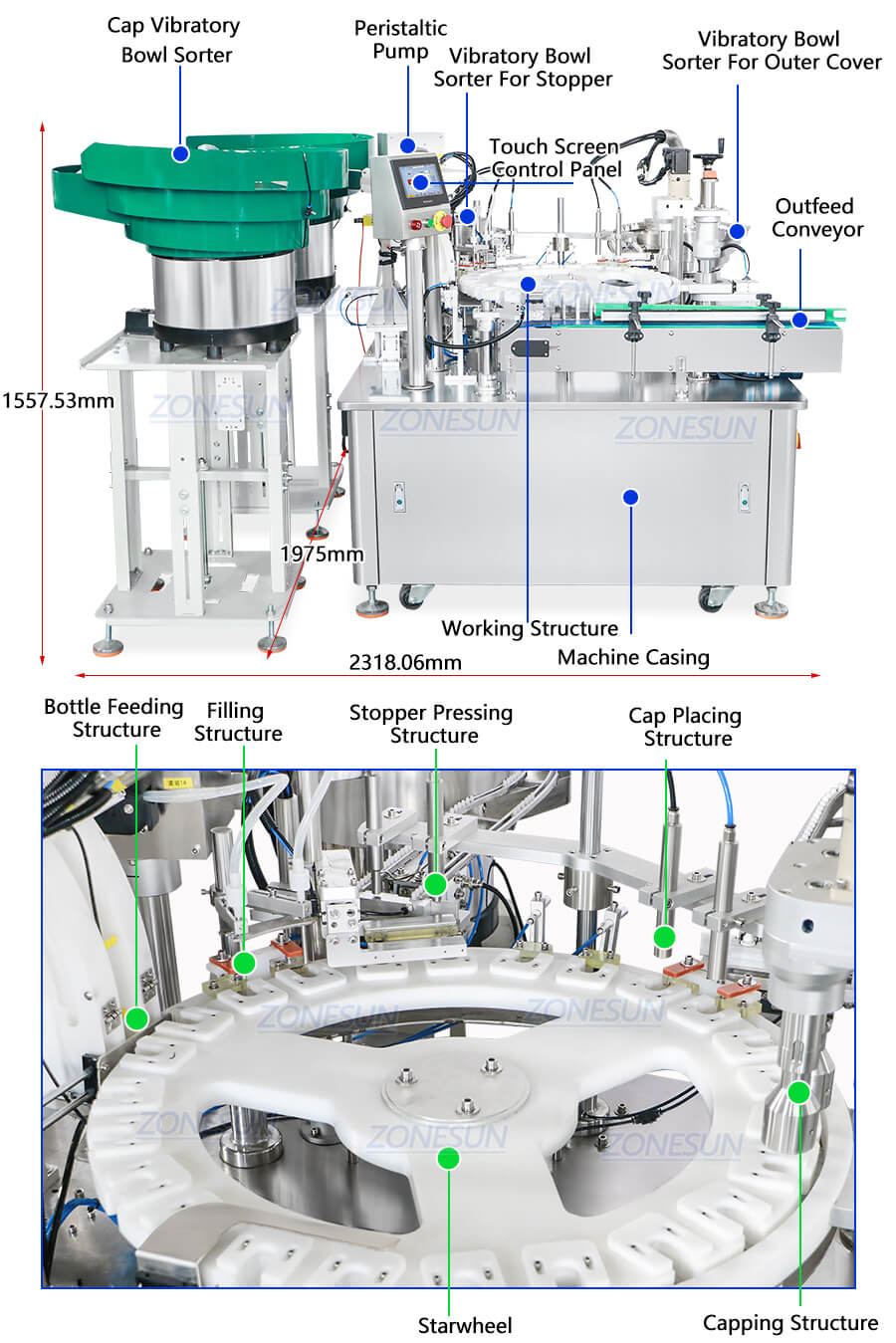

Filling Capping Machine

| Machine Model | ZS-AFC13A |

| Machine Voltage | 110/220V 50-60HZ 8KW |

| Filling Pump | Peristaltic Pump |

| Recommend Filling Range | 45ml (Customizable) |

| Working Speed | 60BPM (based on material and volume) |

| Filling Accuracy | ±2ml (based on material and volume)Suitable Bottle Size |

| Suitable Bottle Size | L52*W24*H94mm (Customizable) |

| Suitable Cap Size | φ18.6*H25.7mm (Customizable) |

| Machine Size | L2318.06*W1975*H1557.53mm |

| Machine Weight | About 1608kg |

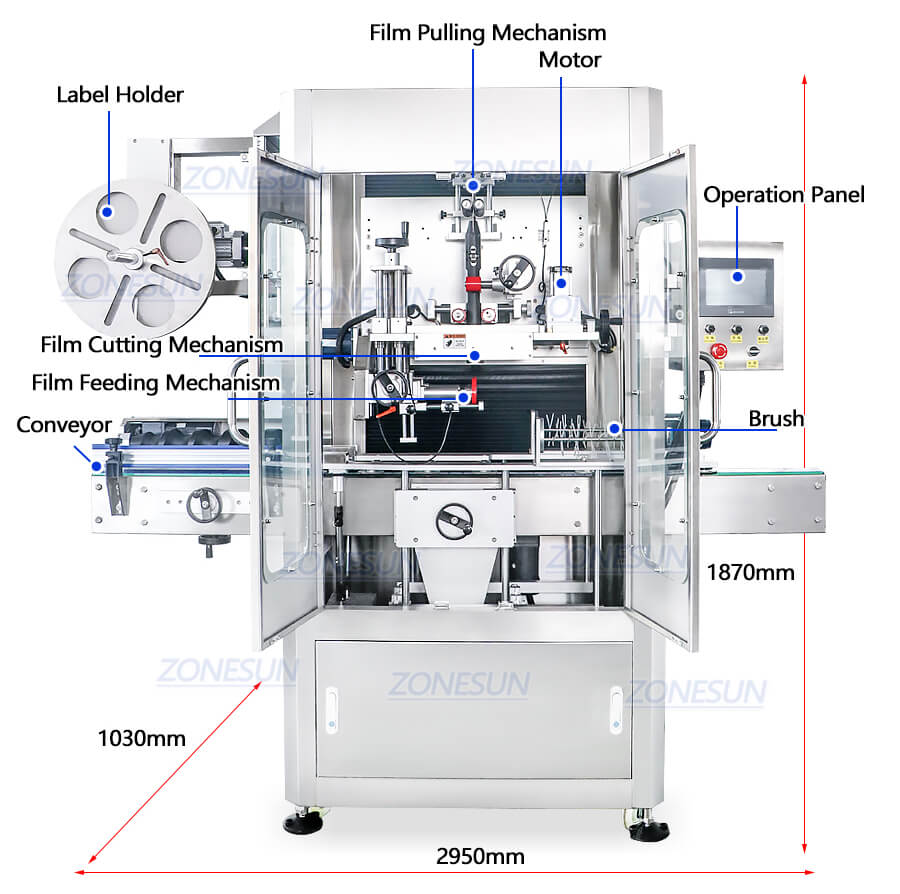

Sleeve Label Machine

| Machine model | ZS-STB150 |

| Bottle diameter range | φ28mm-φ125mm (can be customized) |

| Bottle height | 30 ~ 280 mm (can be customized) |

| Label length | 30~250 mm (can be customized) |

| Label thickness | 0.03 mm ~ 0.13 mm (PVC, PET, OPS, materials are all available) |

| Sleeve standard error | +1.5mm |

| Paper tube inner diameter | 5″~10″ (can be adjusted) |

| Machine speed | 150 bottles/min (based on label length) |

| Voltage | 220V Single Phase |

| Power | 15KW |

| Conveyor belt | standard 2M |

| Machine size | About 2950*10301870 mm(L*W*H) |

| Machine weight | About 464 kg |

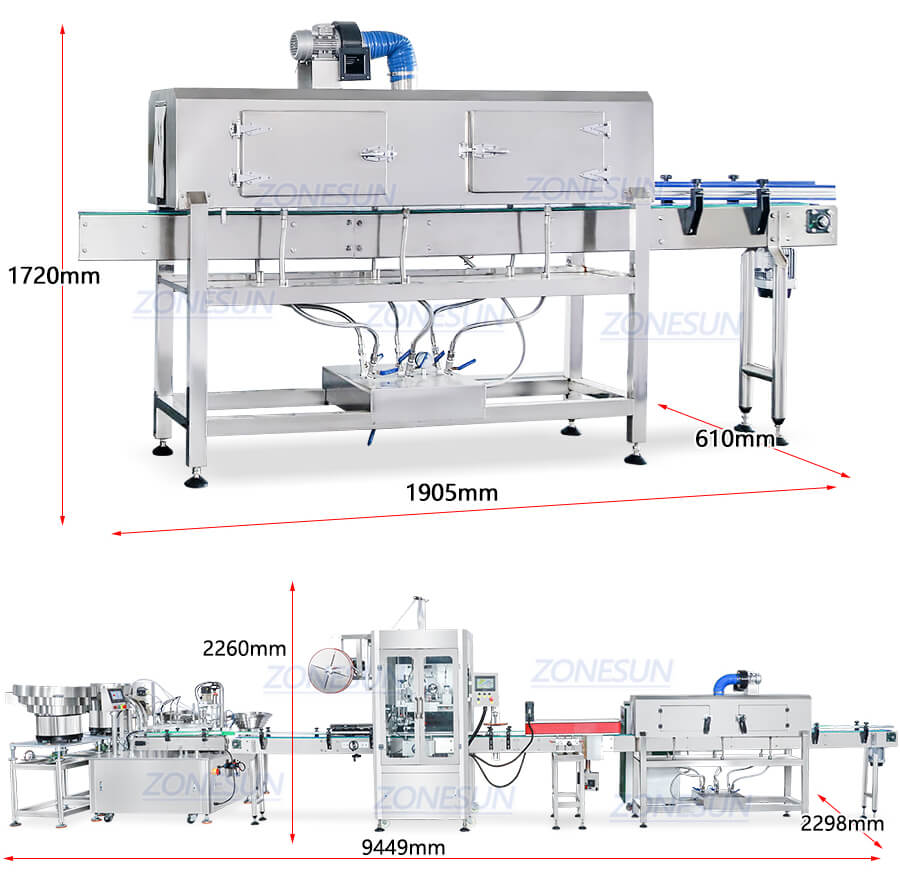

Shrinking Machine

| Tunnel length | About 1800 mm |

| Tunnel width | About 395 mm |

| Tunnel height | About 360 mm |

| Suitable bottle diameter | ≤80 mm |

| Conveyor height | About 900 mm |

| Machine size | About 3050*480*1330 mm(L*W*H) |

| Machine weight | About 86 kg |

| Package size | About 1905*610*1720 mm |

| Package weight | About 143 kg |

Product Details:

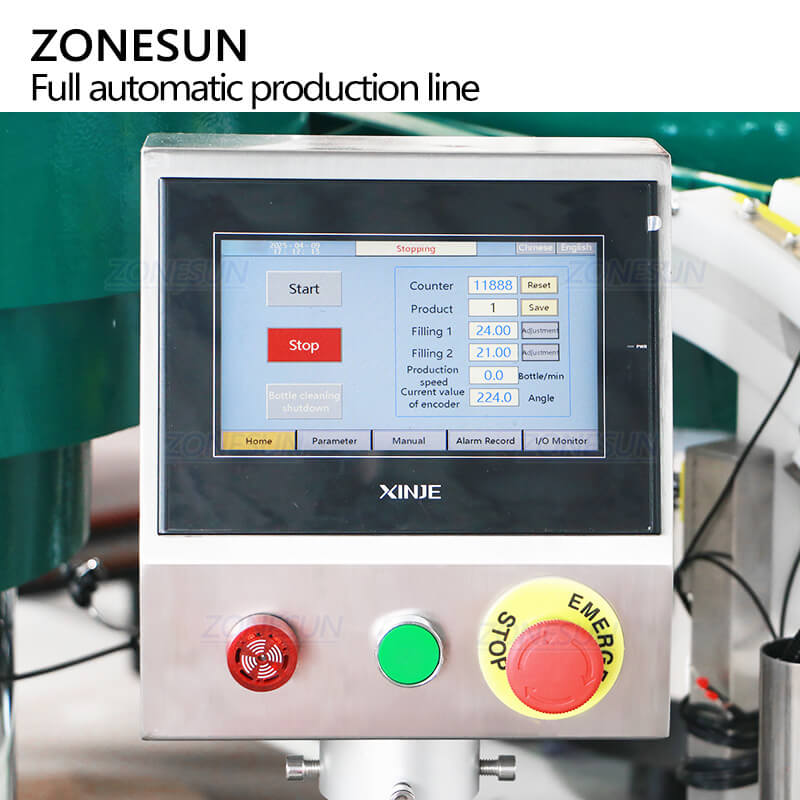

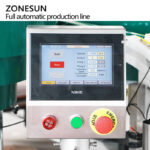

Touchscreen Control Panel

User-friendly HMI interface for easy operation and real-time monitoring.

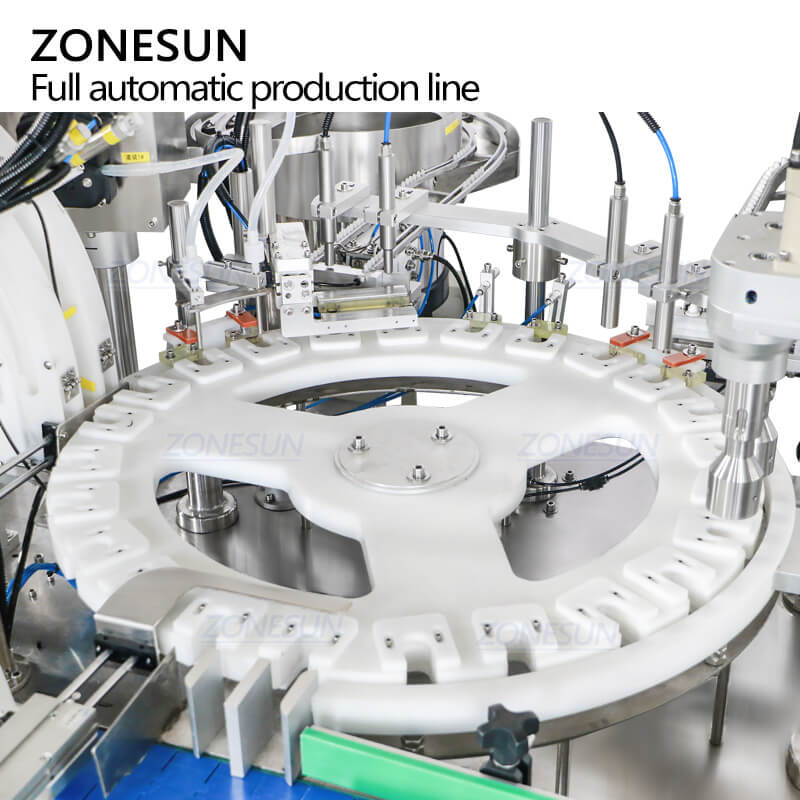

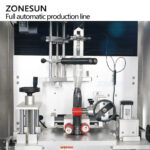

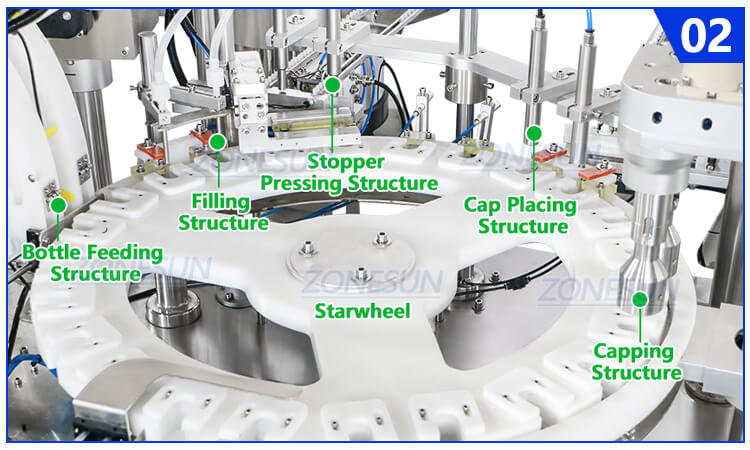

Customizable Starwheel

Modular star wheel design consolidates all functional parts, cam-driven mechanism ensures stable operation at 60BPM.

Peristaltic Pump Filling

Quantitative filling, contamination-free filling as materials only contact the tubing.

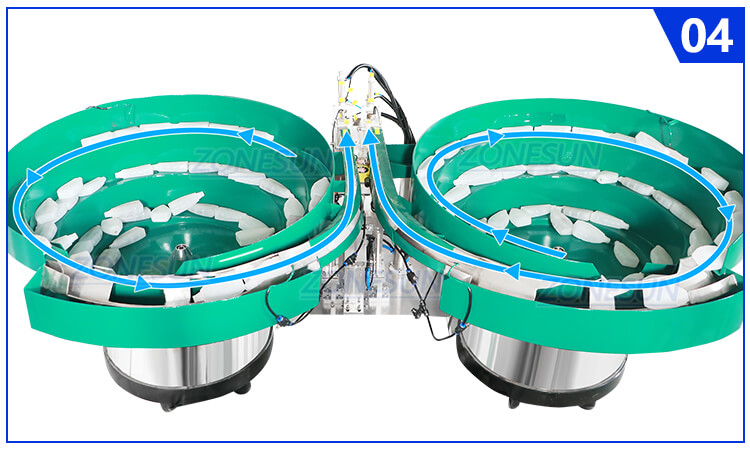

Vibratory Bowl Sorter

Bottles, caps, stoppers are feeded orderly through vibratory bowl sorter, these are customized as needed.

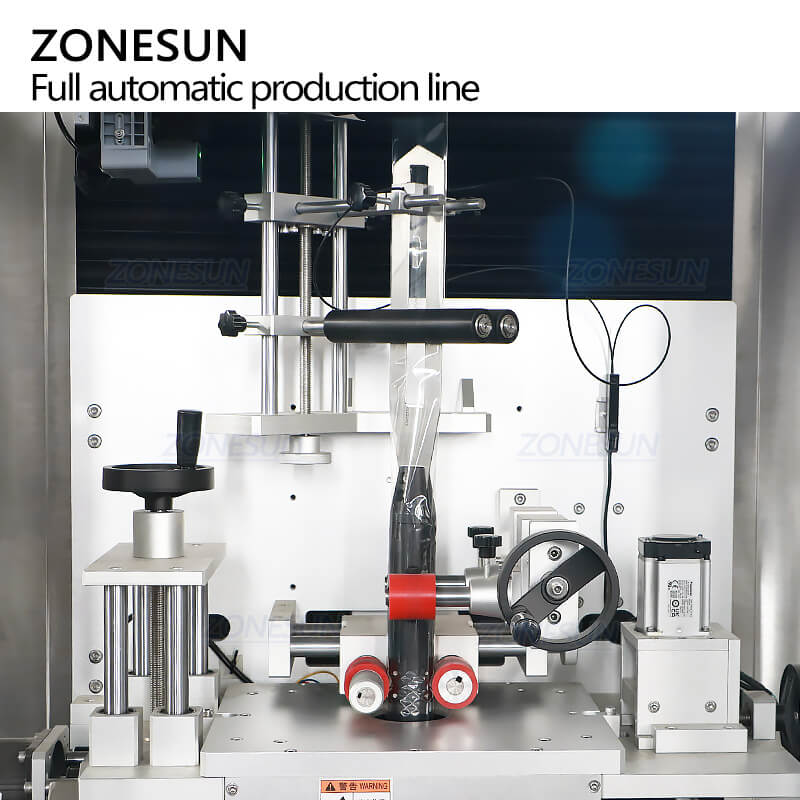

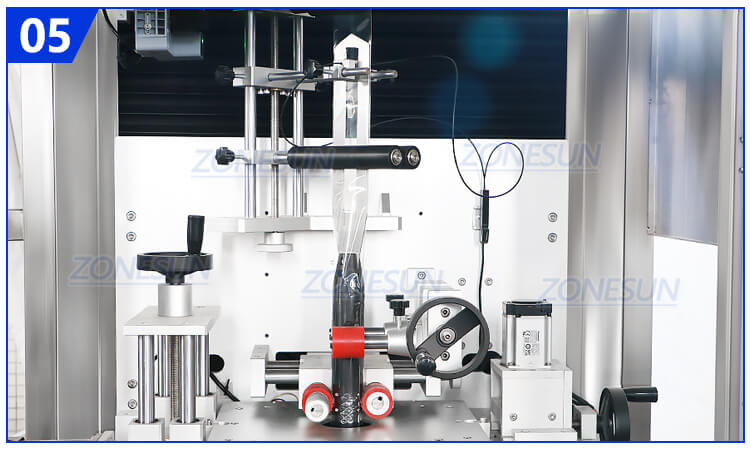

Full-Body Sleeve Labeling

Compatible with PVC/PET/OPS diverse shrink films for seamless labeling.

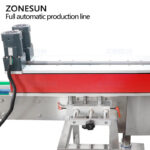

Bottle Bottom Shrinking

Designed for heat shrinking of the bottle body, anti-tip design stabilizes small flat bottles during transport.

Steam Shrink Tunnel

Uniform shrinkage, adapts to round, square, flat, and irregular bottles with even heat distribution.