Product Parameters:

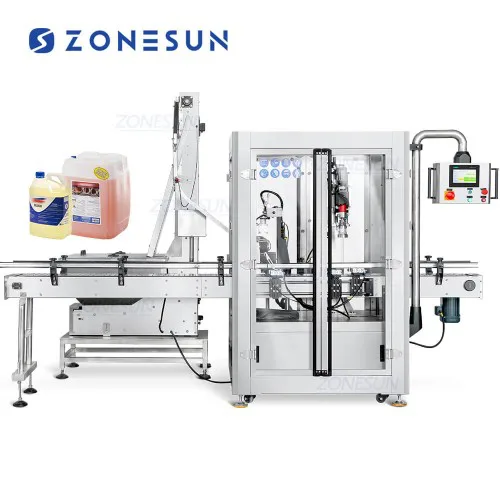

>Monoblock Filling Capping Machine

| Machine Model | ZS-AFC11 |

| Voltage | 220V/110V 50-60Hz |

| Power | 2500W |

| Filling Pump | Peristaltic pump |

| Working Speed | 20-25bottles/min(depending on bottle size and liquid) |

| Max Flow Rate | 4L/min*2(based on water) |

| Suitable Bottle Size | Customized |

| Bottle Cap Diameter | Customized |

| Package Size | About 2040*1660*1650mm |

| Package Weight | About 535kg |

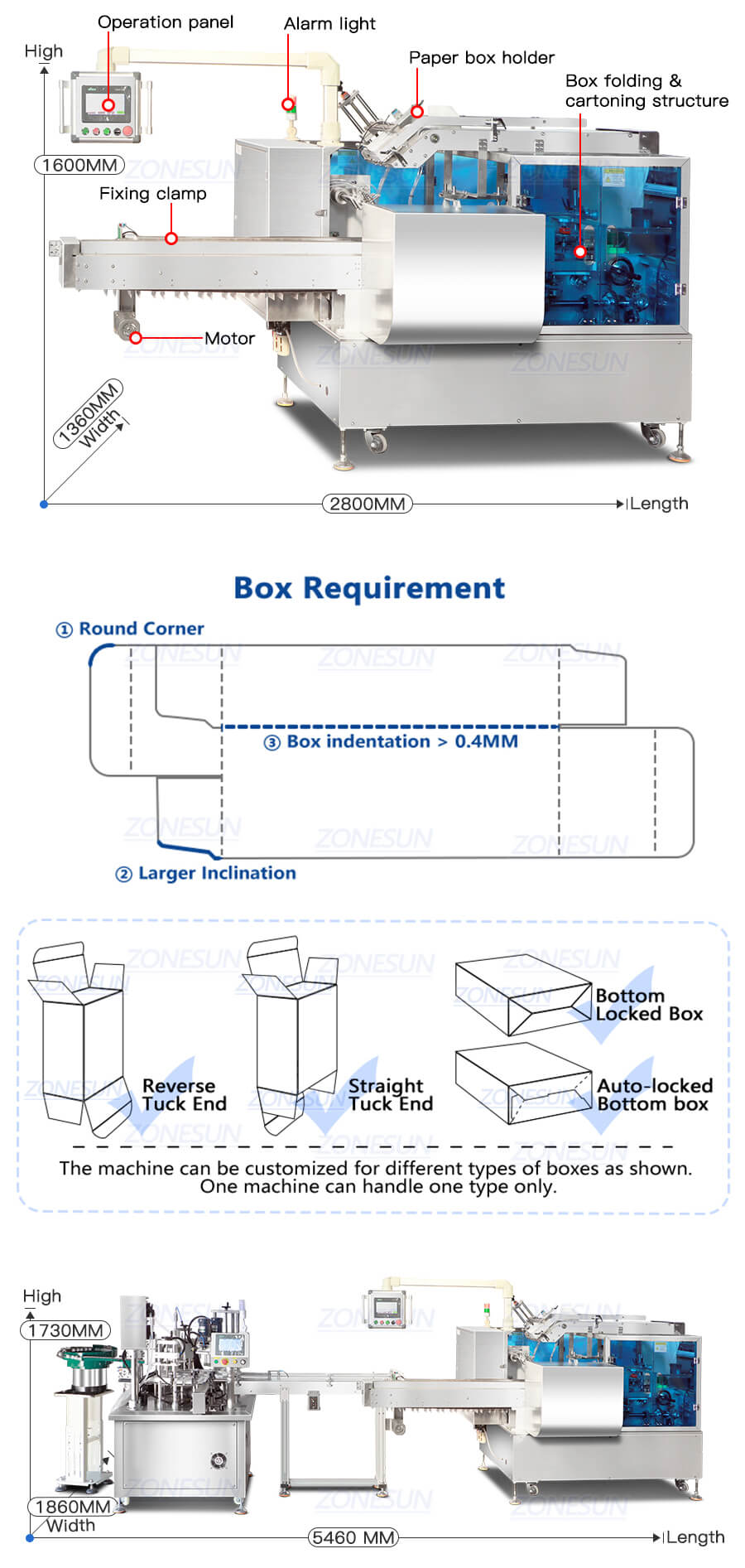

>Cartoning Machine

| Machine model | ZS-MSZH50 |

| Power supply | 110V/220V/380V |

| Power | About 1.5KW |

| Work efficiency | About 30-50 pieces/min |

| Paper box quality requirements | 300-450g/m³(350g/m³ will be best), carton indentation is not less than 0.4MM, with pre-folding effect, no glue leakage in the box |

| Suitable box specifications | About 90-200*30-80*20-50mm(L*W*H)(Can be ordered according to customer requirements) |

| Optional Functions | Leaflet placing/gluing/date coding |

| Air pressure | 0.6-0.8Mpa |

| Air consumption | 130 L/H |

| Machine size | About 2800mm*1360mm*1600mm(L*W*H) |

| Package size | About 3080*1690*1820mm |

| Package weight | About 1095kg |

Product Details:

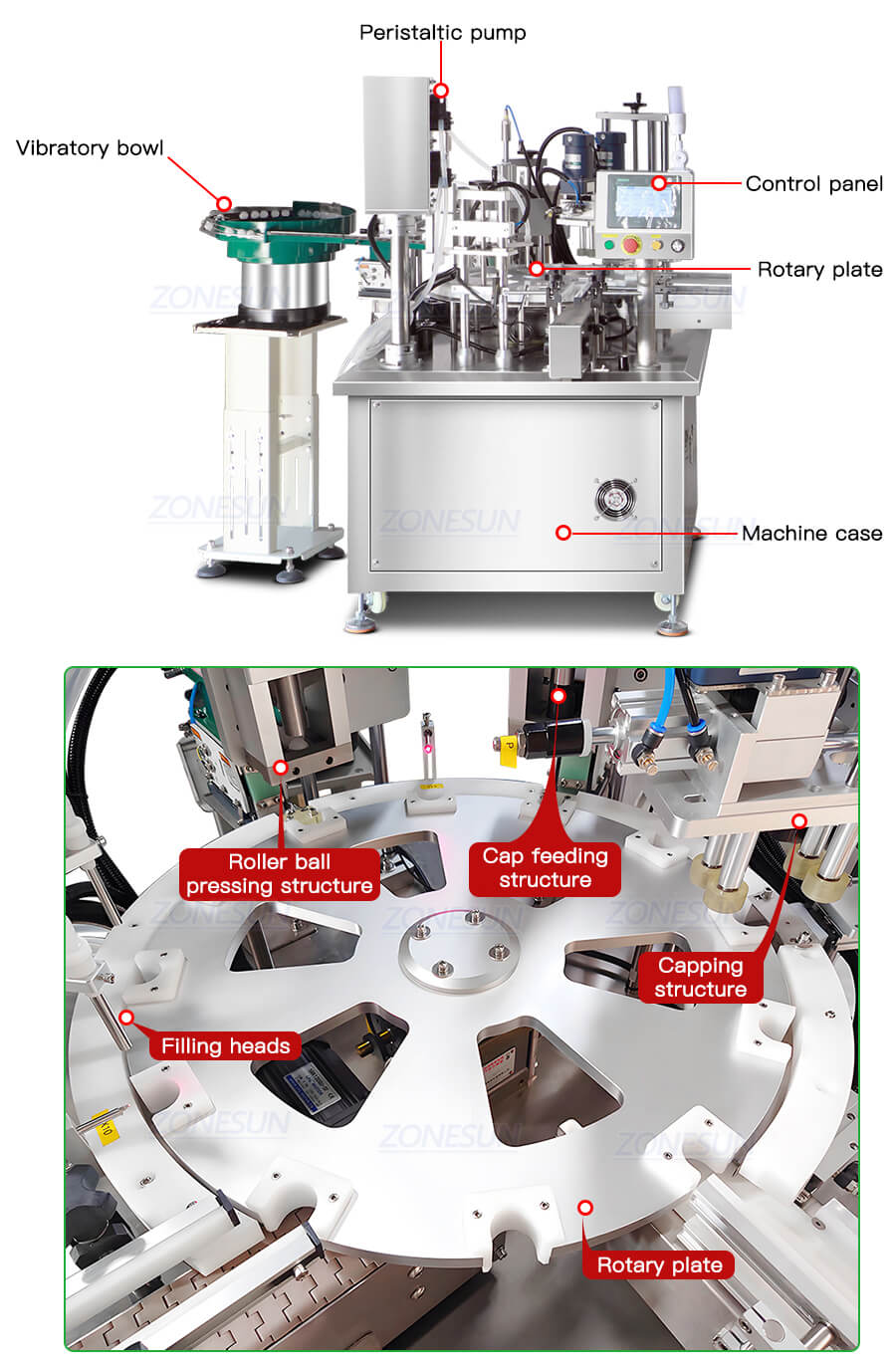

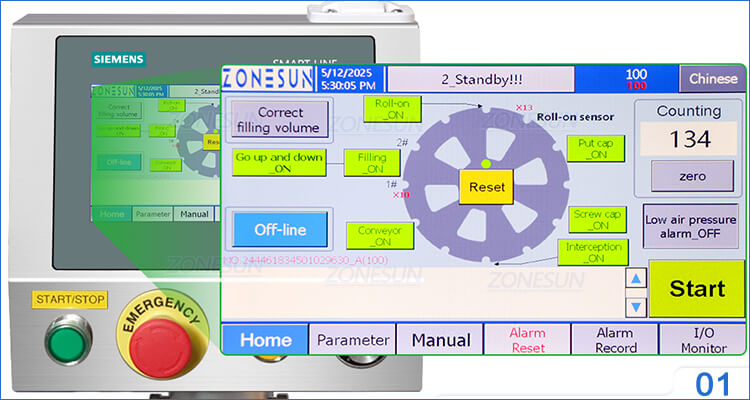

PLC Control Panel

More convenient to set and adjust parameters. Customizable interface simplifies machine operation.

Customizable Starwheel

Capable of filling, roller ball&cap feeding, capping at one machine. The starwheel can be customized as needed.

2 Filling Heads

With peristaltic pumps, liquid only passes through tubing, avoiding contamination.

Vibratory Bowl Sorters

Can feed roller balls and outer caps automatically. The sorters are customized according to your product size.

Product Positioning

Can fix products in a certain position to avoid displacement.

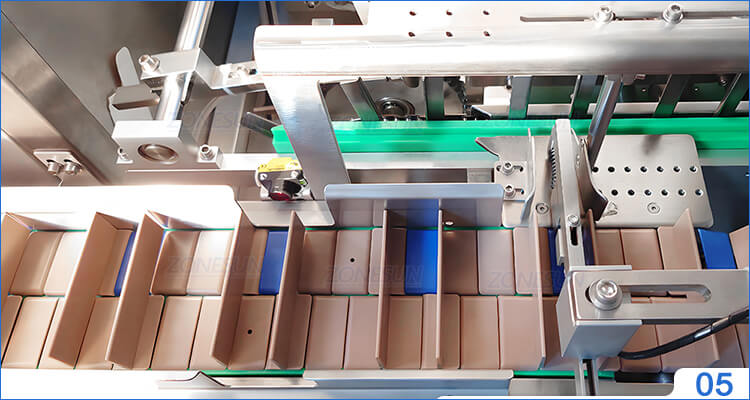

Box Holder

Can be adjusted according to box size. Air nozzles help to erect folded boxes and realize automated work.