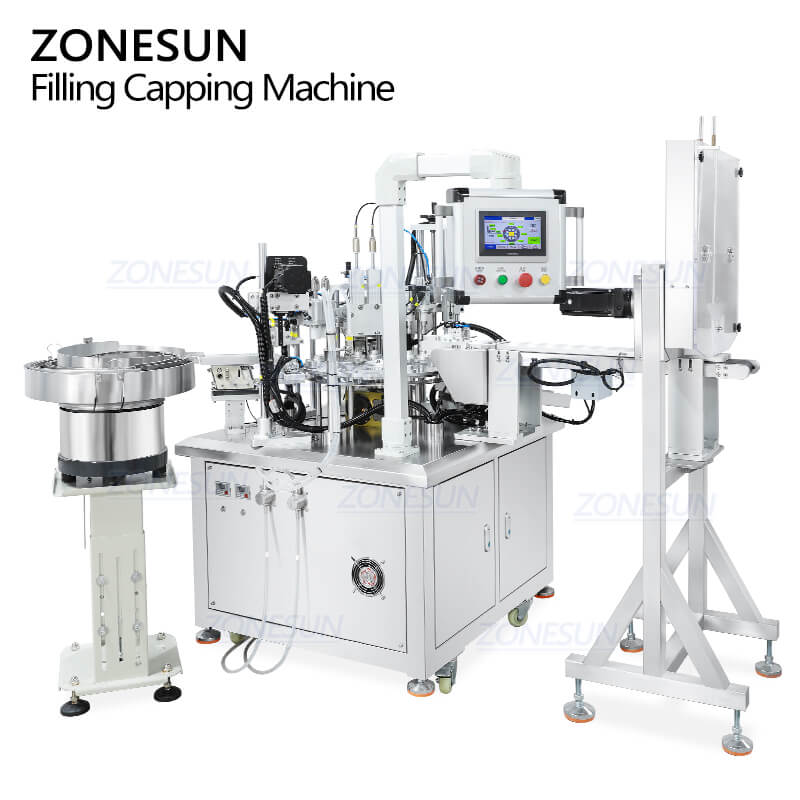

Roller Ball Bottle Filling Capping Machine

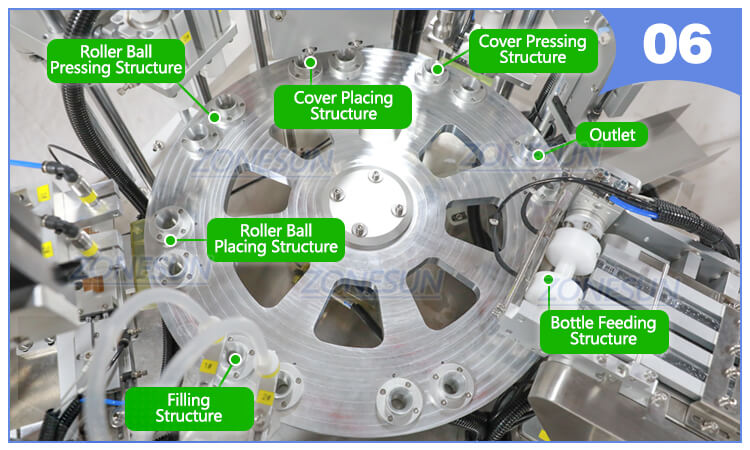

This filling capping machine is designed for small roll-on bottles (can not stand upright during conveying), it can finish bottle feeding, liquid filling, roller ball pressing and outcover pressing, it can be connected with horizontabl labeling machine to finish completed packaging.

Share to

Product Description:

This filling capping machine is designed for small roll-on bottles (can not stand upright during conveying), it can finish bottle feeding, liquid filling, roller ball pressing and outcover pressing, it can be connected with horizontabl labeling machine to finish completed packaging.

Product Parameters:

|

Machine model

|

ZS-AFC17R

|

|

Voltage

|

AC110V/220V, 50-60Hz

|

|

Power about

|

2.5KW

|

|

Filling pump

|

Magnetic Pump

|

|

Number of filling heads

|

2

|

|

Suitable bottle size

|

Φ15-30mm, H=50-120MM

|

|

Suitable cap size

|

Φ15-25mm

|

|

Working speed

|

About 25-40BPM

|

|

Recommended filling volume

|

5-20ml

|

|

Filling accuracy

|

±1%

|

|

Air pressure

|

0.4-0.8MPa

|

|

Machine size

|

About 1937*1866*1628mm

|

|

Machine weight

|

About 480kg

|

|

Package size

|

About 1130*820*570mm(Vibratory+Conveyor)

About 800*650*1870mm(Bracket)

About 1180*1110*1760mm(Main Machine)

|

|

Package weight

|

About 145+125+386kg

|

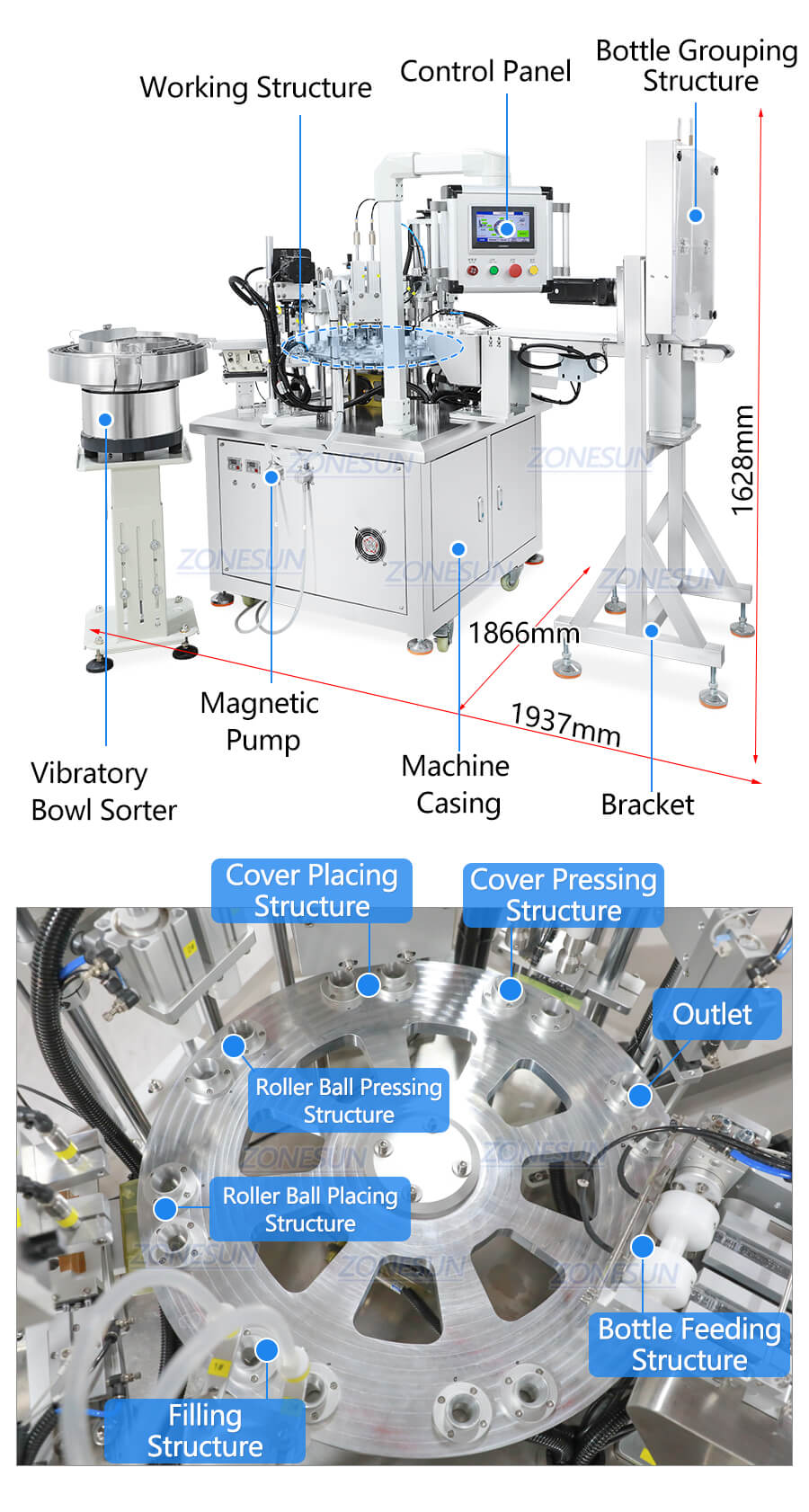

Product Details:

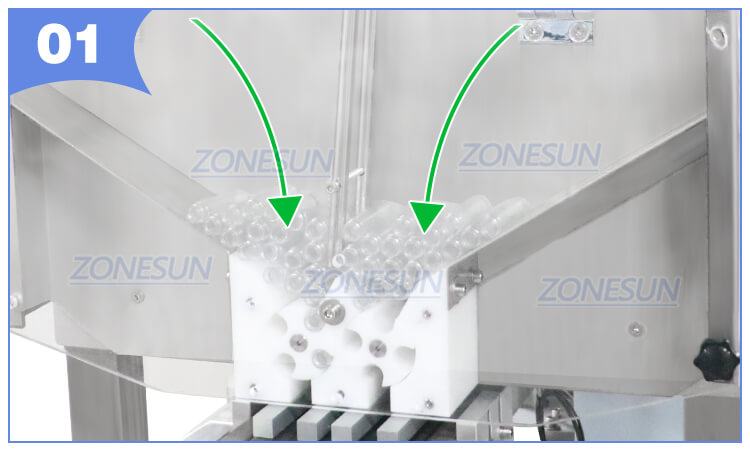

Bottle Grouping Structure

Customizable based on bottle size, it transports bottles in time and orderly.

Control Panel

Equipped with a swing arm, makes parameter setting more convenient & more intuitive.

Vibratory Bowl Sorter

Customizable based on roller ball size, it can feed roller ball in time to ensure smooth work.

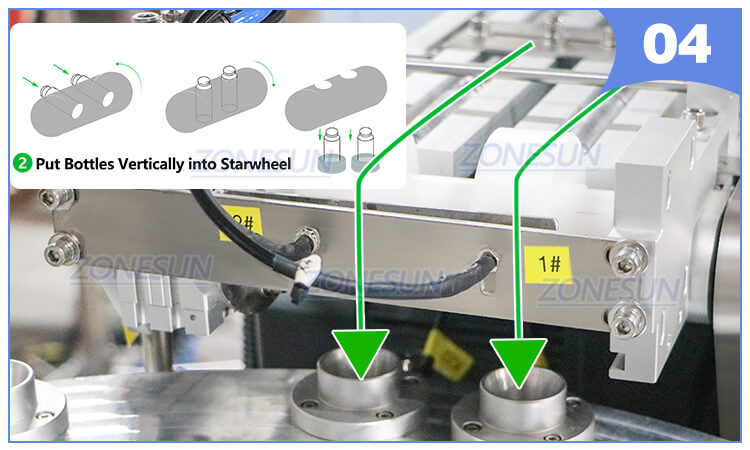

Bottle Feeding Structure

Ensure bottles can be put upright into starwheel, improves working accuracy.

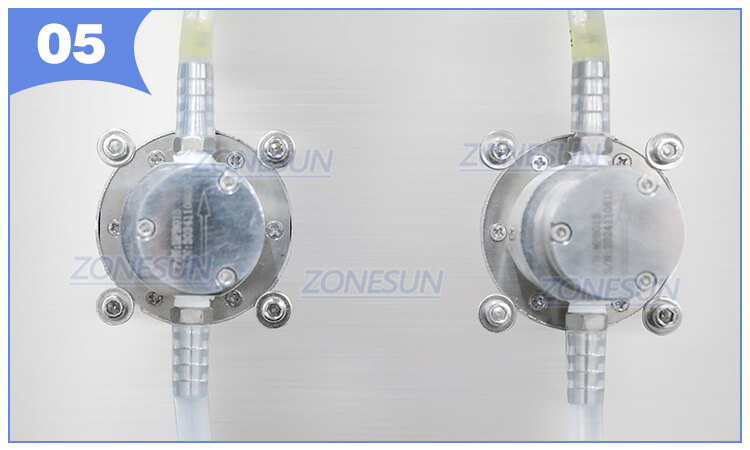

Filling Pump

Equipped with SUS316 magnetic pump, type of filling pump is customizable as production need.

Working Structure

Bottle feeding, filling, stopper pressing & cover pressing are combined together, saves working space.