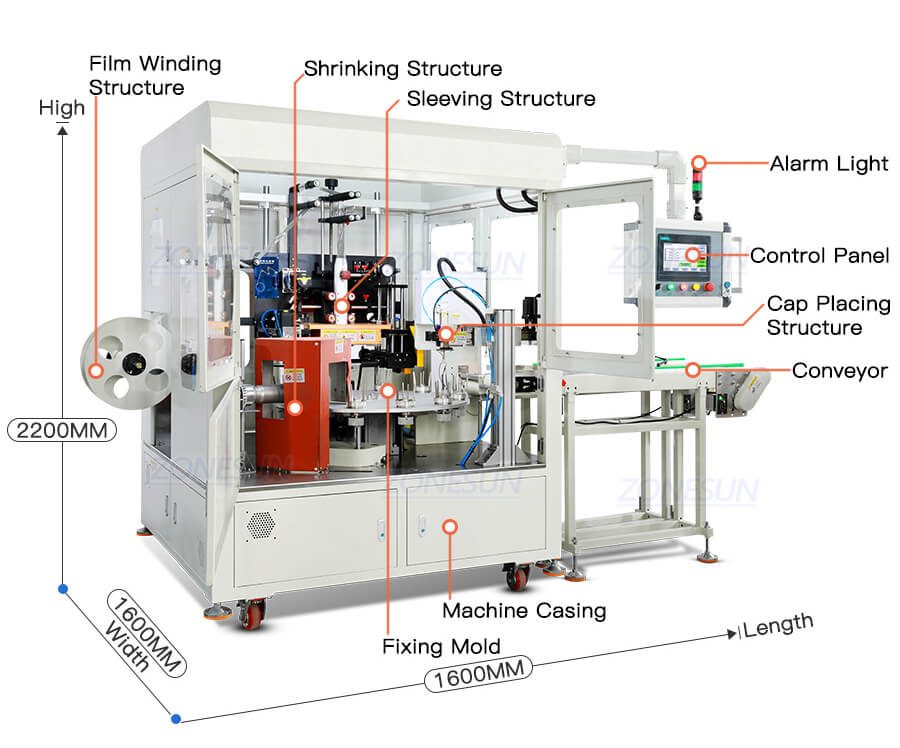

Rotary Shrink Sleeve Labeling Machine

This rotary shrink sleeve labeling machine is equipped with a temperature control system with adjustable constant temperature, featuring a turntable structure design that occupies a small area. It has an automatic fault alarm function and one-click intelligent operation. The mold can be changed to accommodate bottles of different sizes. The servo motor control enhances transmission efficiency.

Share to

Product Description:

This rotary shrink sleeve labeling machine is equipped with a temperature control system with adjustable constant temperature, featuring a turntable structure design that occupies a small area. It has an automatic fault alarm function and one-click intelligent operation. The mold can be changed to accommodate bottles of different sizes. The servo motor control enhances transmission efficiency.

Product Parameters:

| Model | ZS-UDTB50 |

| Power supply | AC380-4p 50~60HZ |

| Total power | 6KW/H |

| Thickness of roll film | 0.04-0.045mm |

| Packaging size | 90-130mm(Φ) *15-50mm(H) |

| Packing speed | 45-60PCS |

| Working air pressure | 0.5MPS |

| Machine size | About 1600*1600*2200mm |

| Machine weight | About 1000kg |

Product Details:

Control Panel

Touch screen control panel makes parameter setting more convenient,multiple languages are customizable.

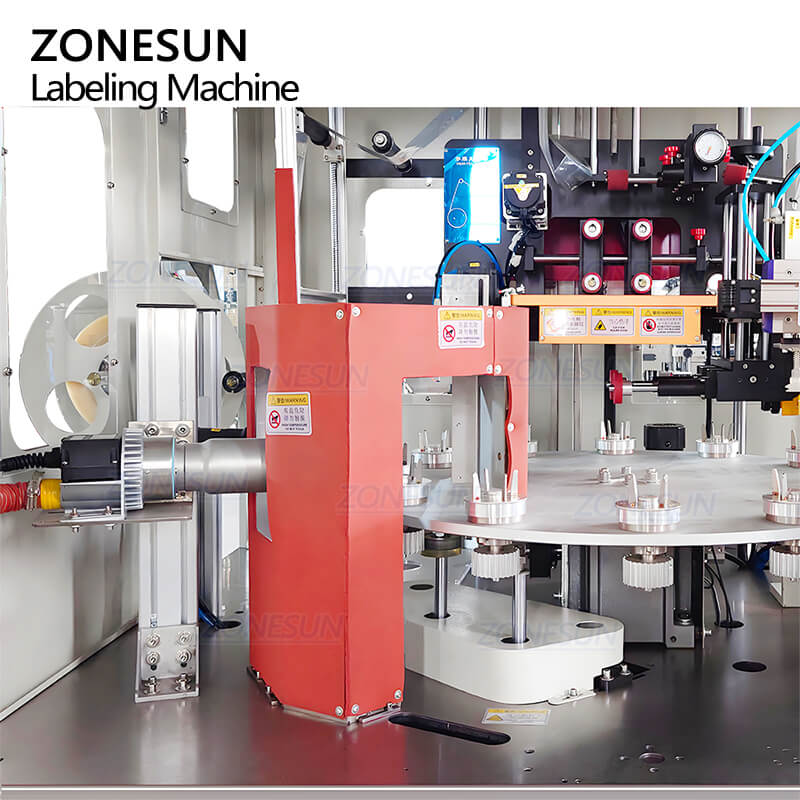

Bottle Placing Structure

Using a robotic arm to place bottles, it improves work accuracy.

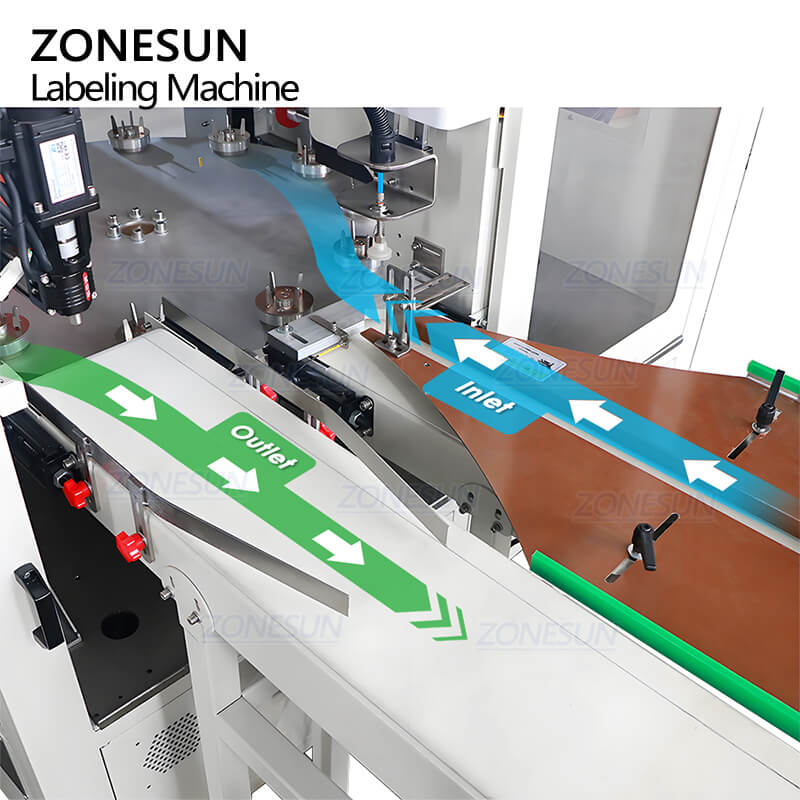

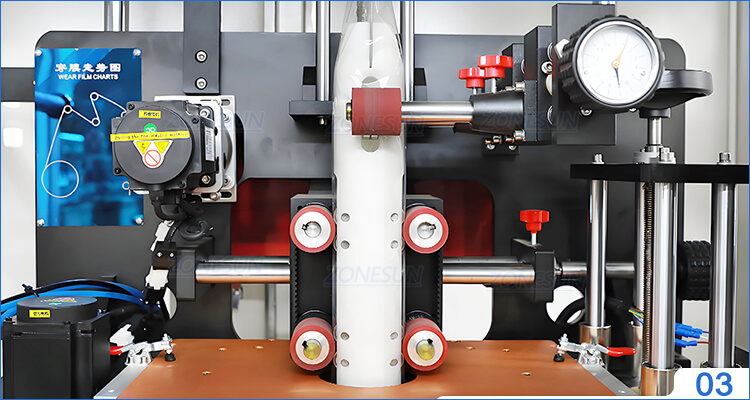

Sleeve Structure

It can handle various container of different heights and diameters.

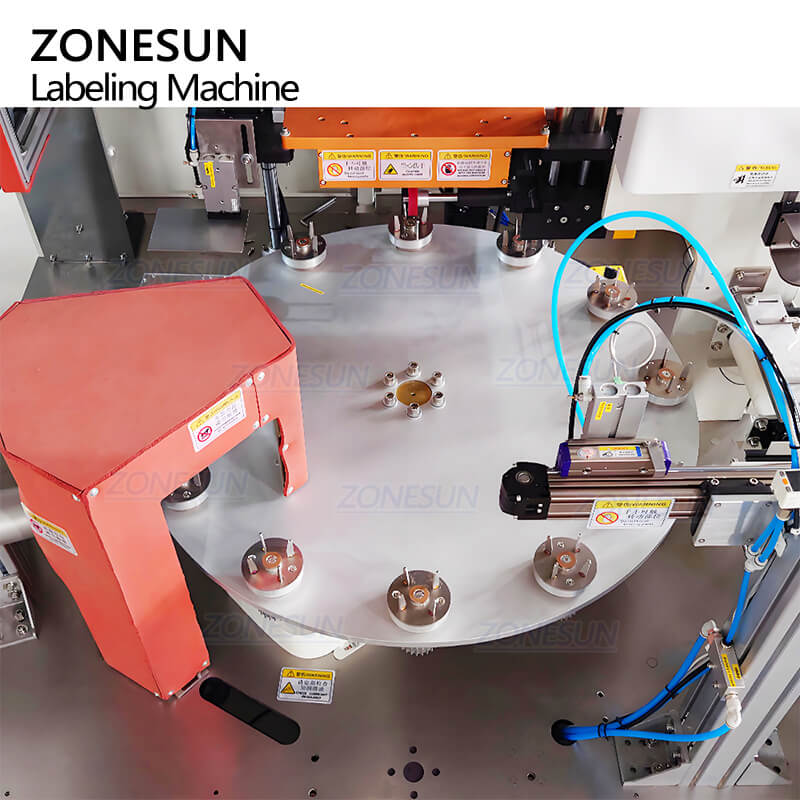

Rotary Design

Bottle placing, sleeving, shrinking at one starwheel, it saves working space.

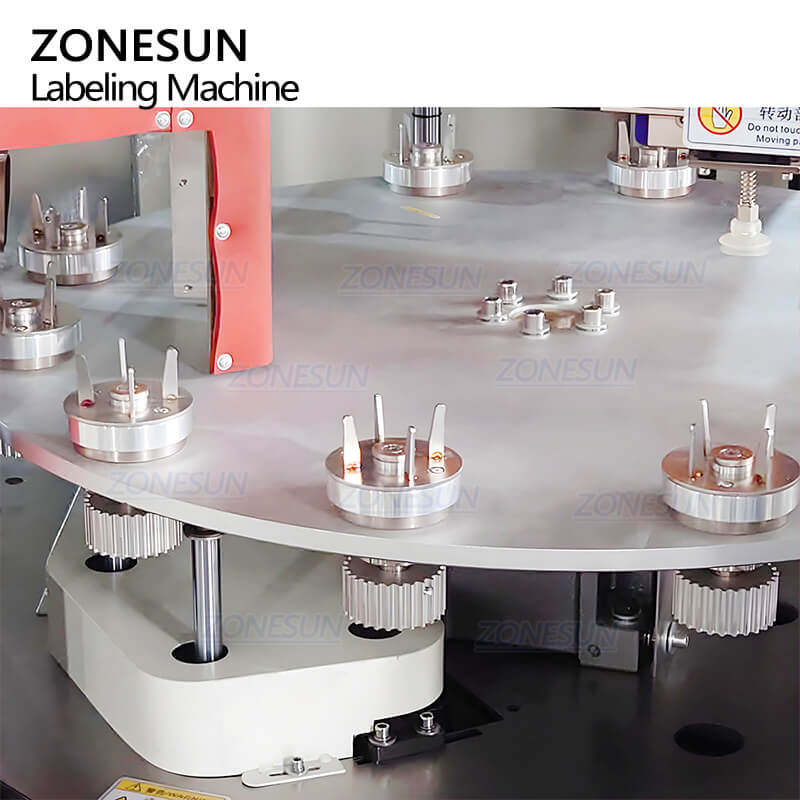

Bottle Fixing Molds

These are changable according to different sizes of bottles, it has wider application range.

Shrinking Structure

Using hot air to shrink packaging film, faster working speed and suitabe for regular containers or products.

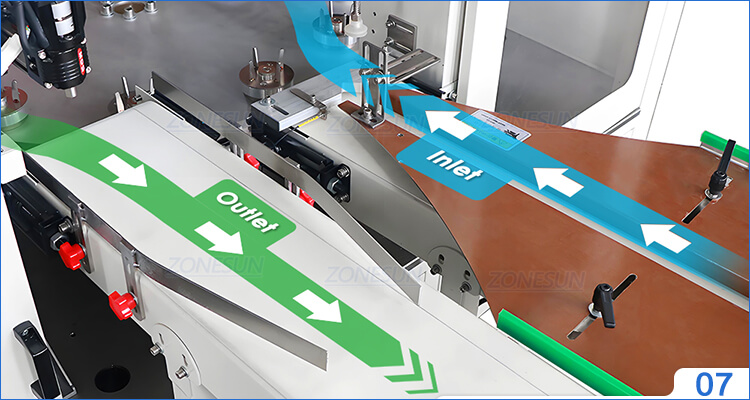

Conveyor

Using conveyor to transport finished products in time, it saves working labor.