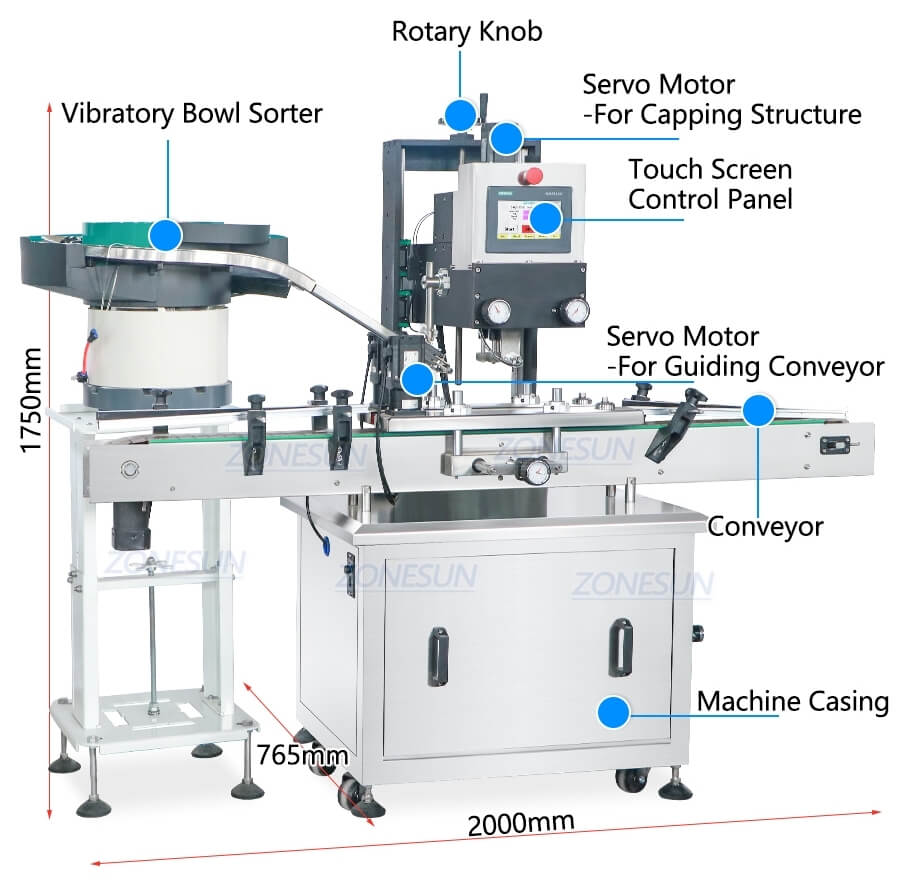

Servo Bottle Capping Machine

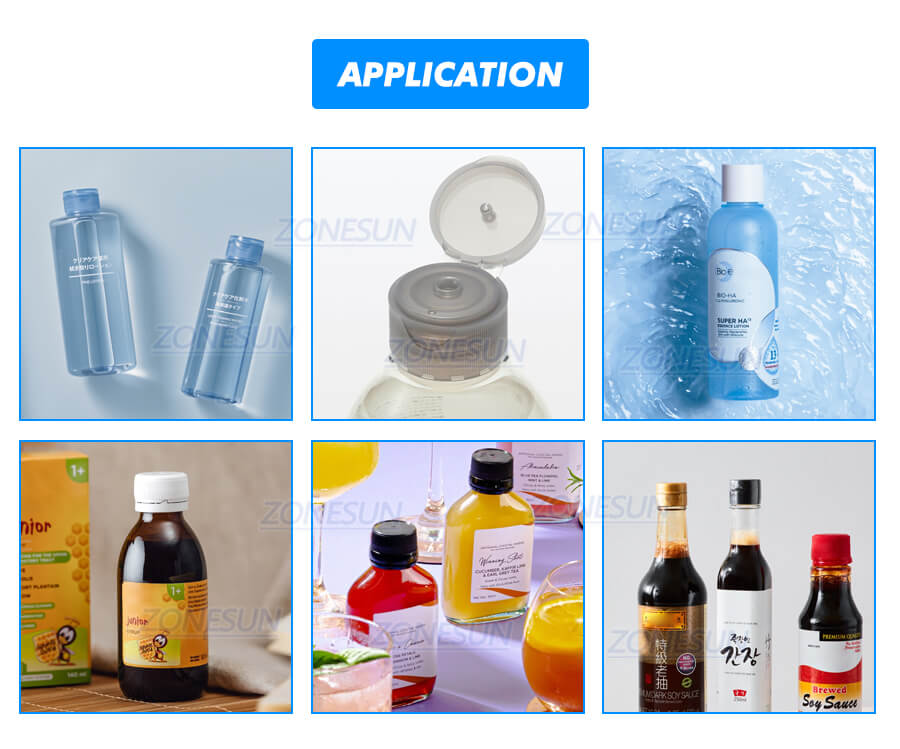

This servo capper is equipped with vibratory bowl sorter with 2 guide rail, which can be changed to feed two kinds caps, this can save production cost.It can integrate with filling and labeling machine to realize automated production.

Share to

Product Description:

Product Description:

This servo capper is equipped with vibratory bowl sorter with 2 guide rail, which can be changed to feed two kinds caps, this can save production cost.It can integrate with filling and labeling machine to realize automated production.

Product Parameters:

Product Parameters:

| Machine model | ZS-XG440S2 |

| Voltage | 110/220V 50-60HZ |

| Machine power | About 3.55KW |

| Suitable bottle size | H=50-300mm φ=30-120mm |

| Suitable cap size | φ=20-60mm(Size of two caps needs to be close) |

| Working speed | About 40 bottles/min |

| Machine size | About 2000mm*765mm*1750mm |

| Machine weight | About 400kg |

| Package size | About 2060*800*1860mm |

| Package weight | About 450kg |

Product Details:

Product Details:

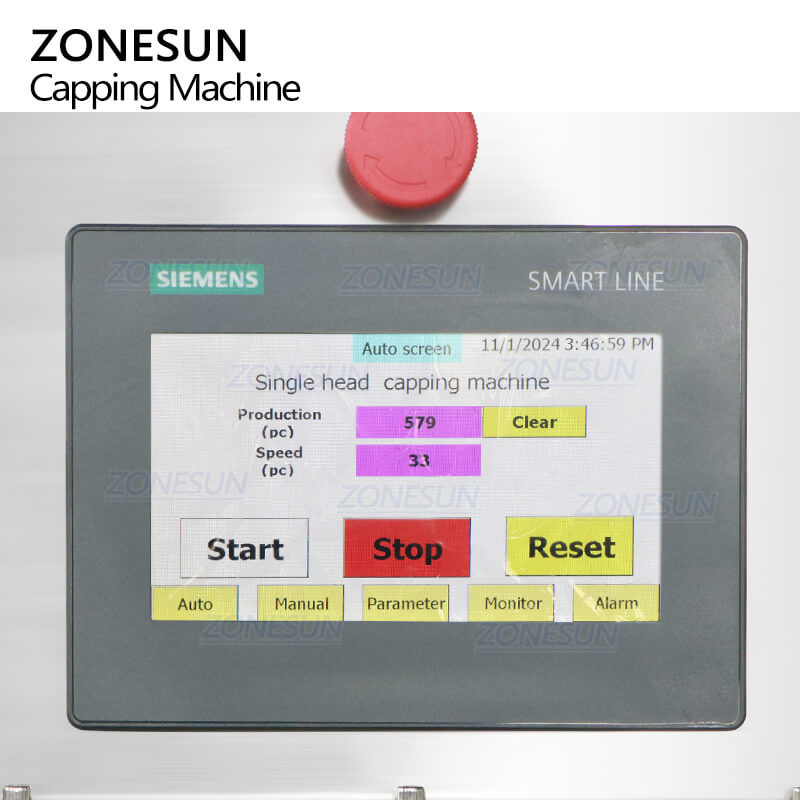

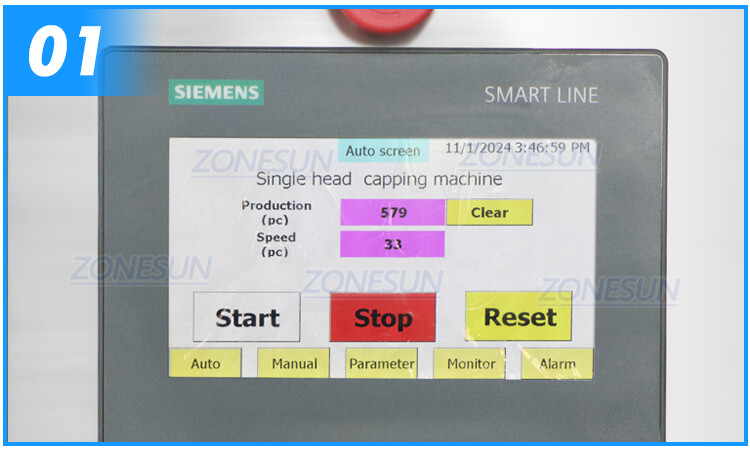

Control Panel

Touch screen control panel makes parameter setting more convenient, multi languages are customizable.

Vibratory Bowl Sorter

Vibrating machine with two guide rail, this is suitable for 2 caps with similar sizes, it is no need to change parts.

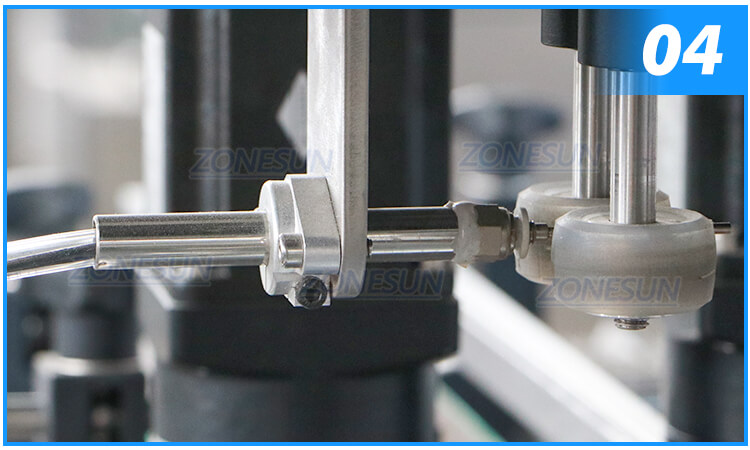

Capping Structure

Controlled by servo motor, capping accuracy and working capacity can be improved greatly.

Electric Eye

This can detect passing by bottles and control the machine to work automatically.

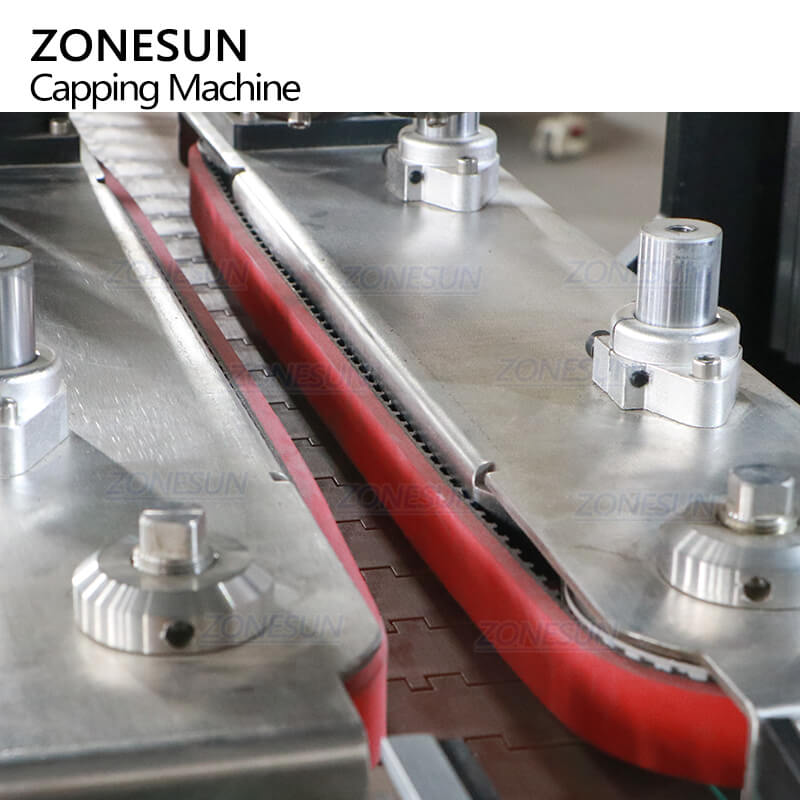

Guiding Conveyor

It is controlled by servo motor, this can save working labor for adjusting machine.

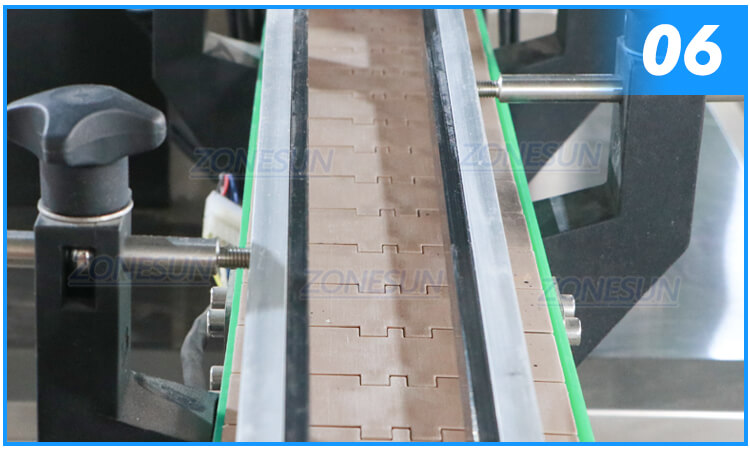

Chain Conveyor

Length and width can be customized as production need, it has larger weight capapcity when integrate with filling machine.