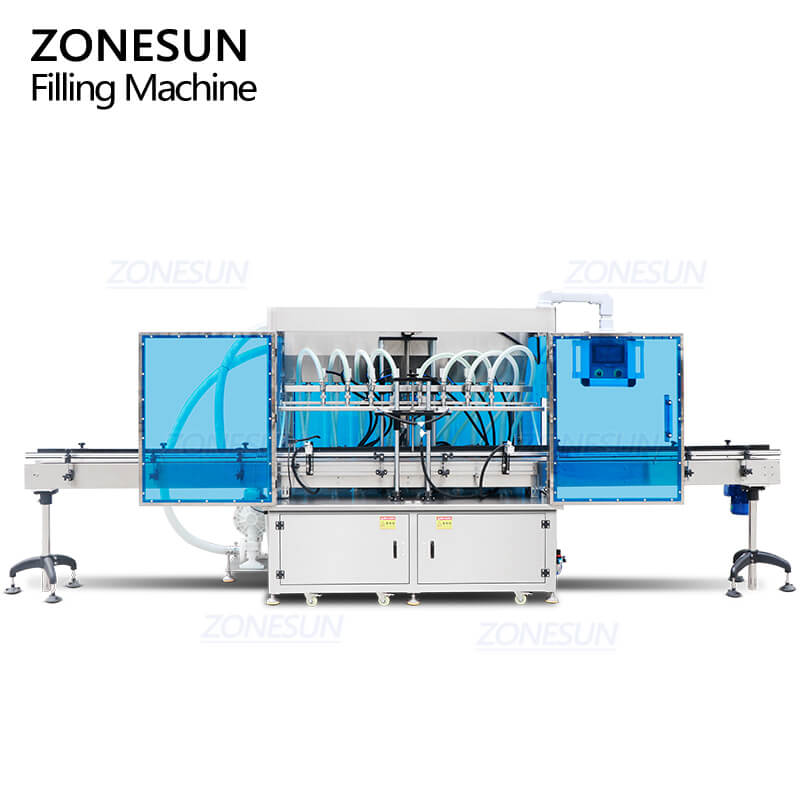

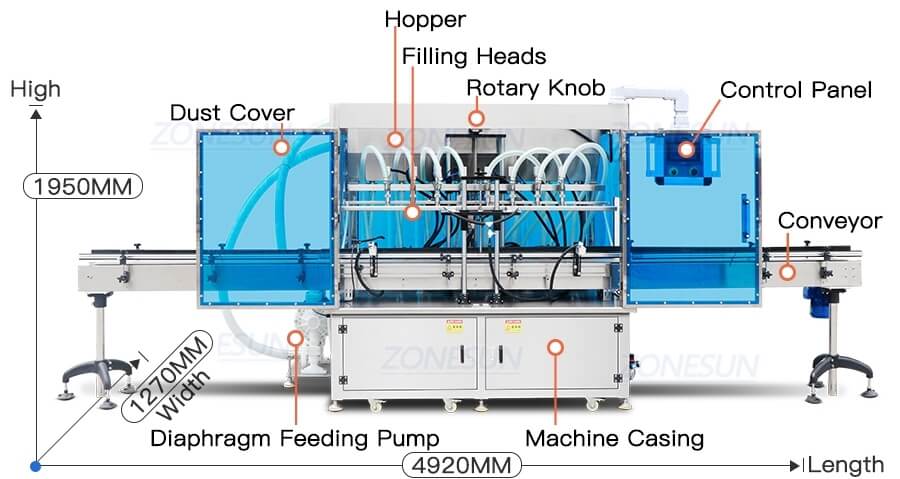

Servo Gear Pump Cosmetic Filling Machine

This servo motor-controlled automatic filling machine ensures precise quantitative filling, enabling effortless operation. Operators can easily set filling parameters directly via the intuitive control panel. Equipped with a continuous feeding pump system, it maintains consistent material supply for highly efficient processing of free-flowing liquids and viscous substances, including laundry detergents, lotions, cosmetic serums, and similar formulations.

Share to

Product Description:

This servo motor-controlled automatic filling machine ensures precise quantitative filling, enabling effortless operation. Operators can easily set filling parameters directly via the intuitive control panel. Equipped with a continuous feeding pump system, it maintains consistent material supply for highly efficient processing of free-flowing liquids and viscous substances, including laundry detergents, lotions, cosmetic serums, and similar formulations.

Product Parameters:

| Machine model | ZS-VTGF8A |

| Power supply | 110/220V 50-60HZ 5KW |

| Filling pump | Gear Pump |

| Max flow rate | 120L |

| Filling range | 50-5000ml |

| Bottle size | Customizable |

| Working speed | About 24-40 bottles/min (based on 5L filling volume) |

| Filling accuracy | About ±0.5% |

| Air pressure | About 0.5-0.8MPa |

| Machine size | About 4920*1270*1950mm |

| Package size | About 2720*1350*2120mm |

| Package weight | About 630kg |

Product Details:

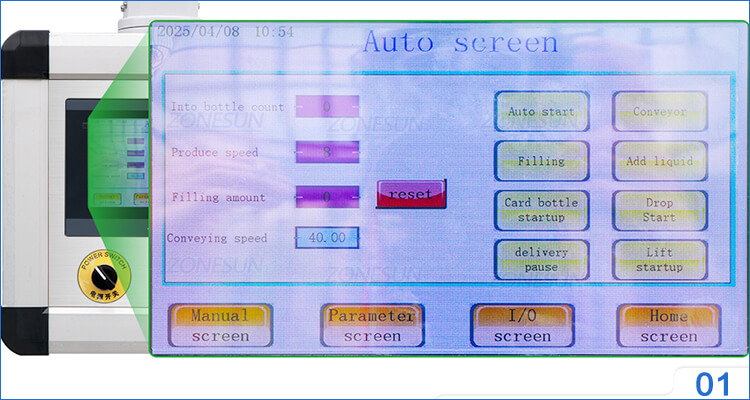

Touchscreen Interface

Simple and intuitive parameter setting with a user-friendly swing-arm design for easier operation.

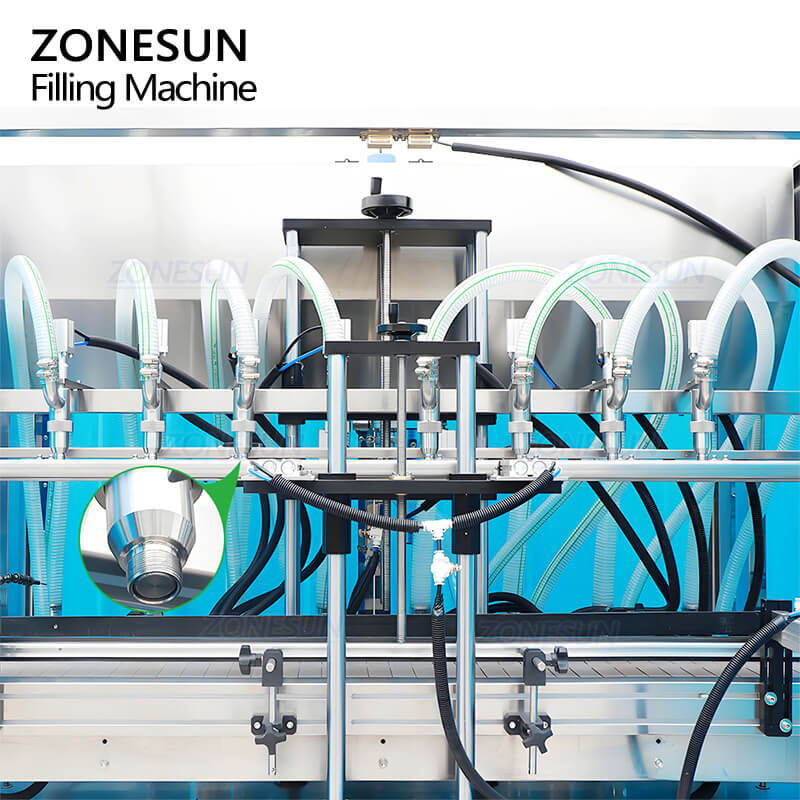

Filling Nozzles

Equipped with anti-dripping nozzles, the number of nozzles can be customized according to production needs.

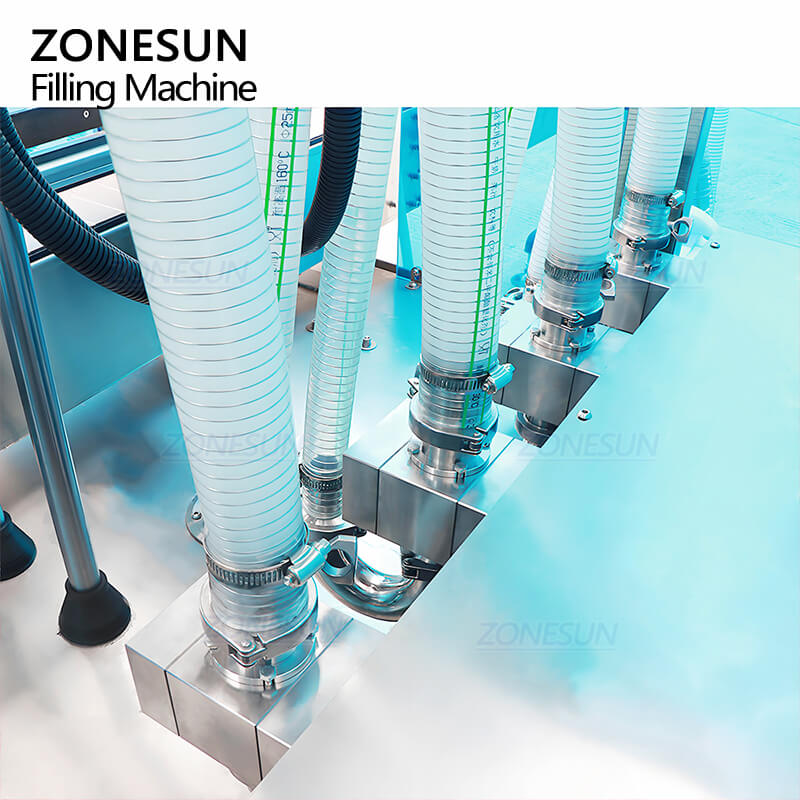

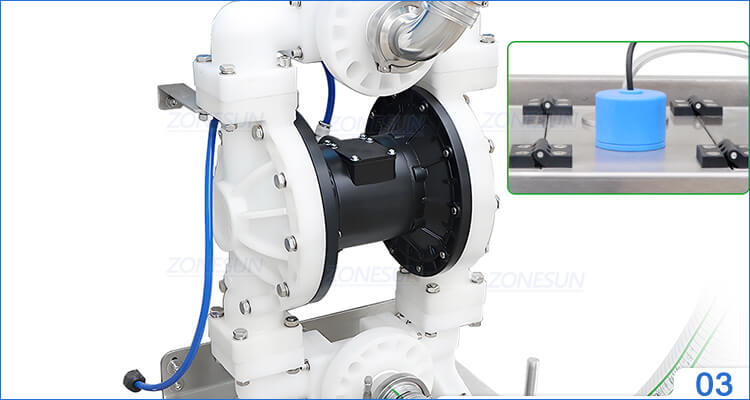

Diaphragm Feeding Pump

Material levels are detected via a sensor above the hopper, ensuring timely material replenishment.

Servo Gear Pump Control

The filling process is driven by a servo gear pump for high accuracy and consistent volumetric filling.

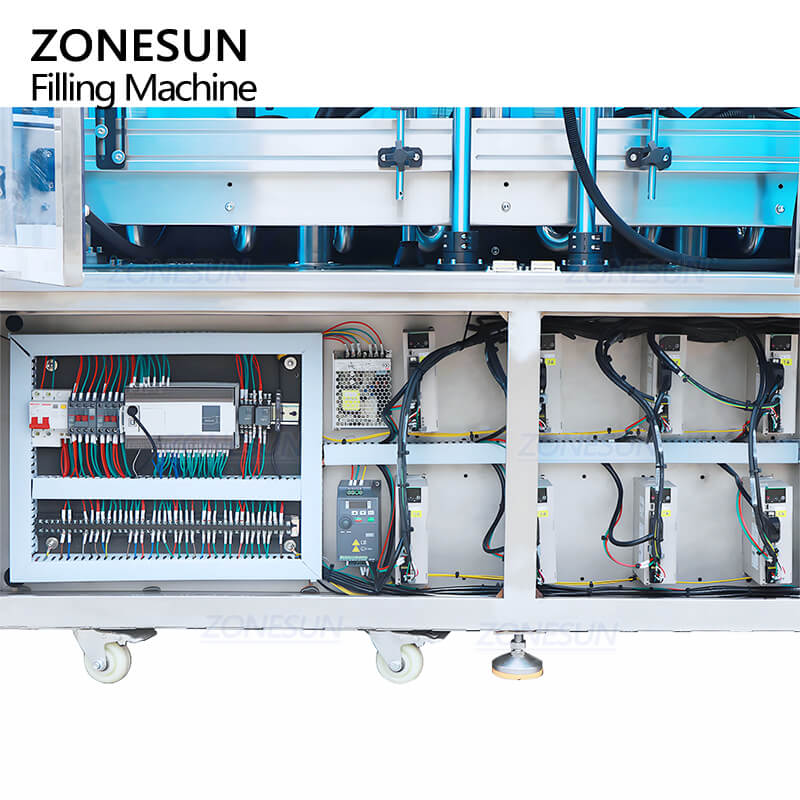

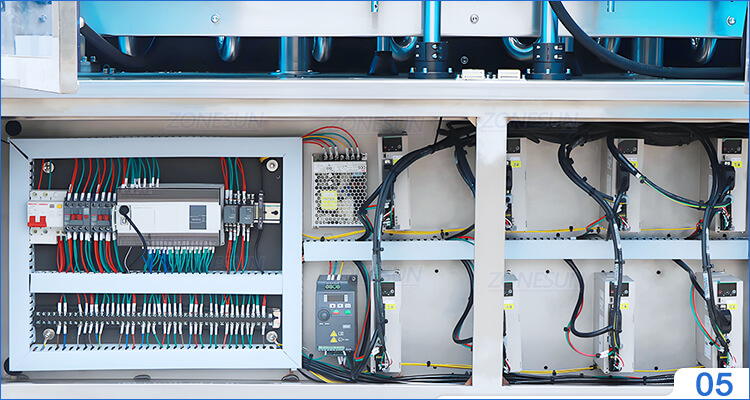

Organized Electrical Layout

Neat and structured wiring layout ensures stable operation and simplifies maintenance.