Soft Tube Filling Sealing Machine

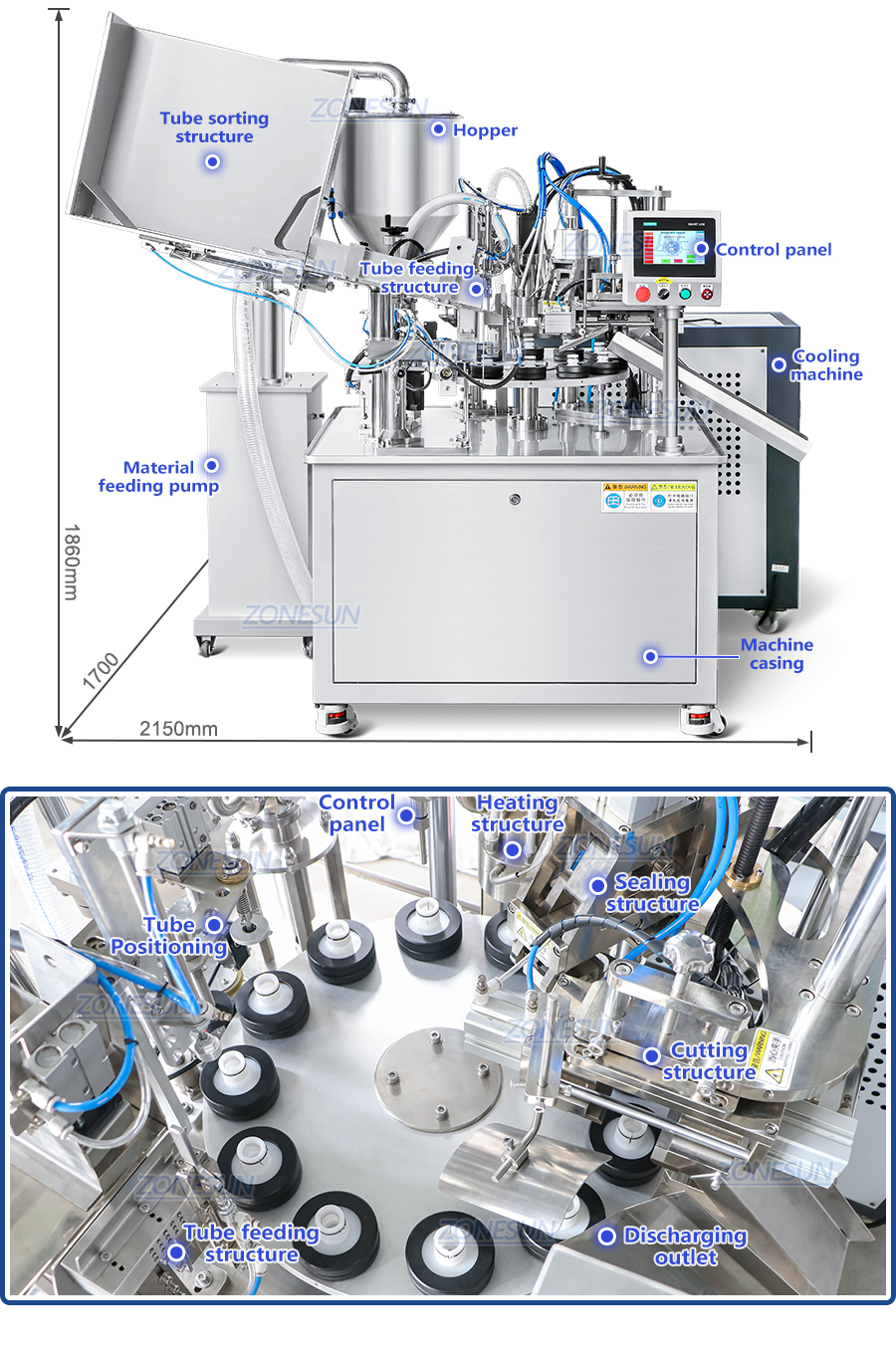

This filling and sealing machine is capable of simultaneously completing tube feeding, paste filling, tube sealing, and cutting, as well as date stamping and finished product discharge. It’s ideal for packaging plastic and aluminum-plastic composite soft tubes.

Share to

Product Description:

This filling and sealing machine is capable of simultaneously completing tube feeding, paste filling, tube sealing, and cutting, as well as date stamping and finished product discharge. It’s ideal for packaging plastic and aluminum-plastic composite soft tubes.

Product Parameters:

| Machine model | ZS-FS007U |

| Voltage | 110/220V 50-60HZ 4.5KW |

| Tubematerial | plastic soft tube, compositesofttube |

| Tubediameter | φ16-φ50mm |

| Tubelength | 80-220mm (customizable) |

| Filling capacity | 4-30ml/30-150ml/50-300ml (optional, adjustable)) |

| Filling method | servo piston filling |

| Filling accuracy | ±1% |

| Production efficiency | 20-50 pieces/min(based onfilling volume and filling materials) |

| Working air pressure | 0.6-0.8mpa |

| Heat sealing power | 3.3KW |

| Machinesize | About 1050*550*1070mm(L*W*H) |

| Package size | About 1720*1110*2030mm(Main Machine)

About 460*440*1230mm(Cooling Machine) |

| Package weight | About 760kg(Main Machine)

About 37kg(Cooling Machine) |

Product Details:

Touch Screen Control Panel

Working parameter settings are completed directly on the operation panel.

Working parameter settings are completed directly on the operation panel.

Tube Positioning

Can position soft tube before filling, improves working accuracy

Can position soft tube before filling, improves working accuracy

Precision Cam System

Each working station works at the same time, it can reach 30-50 pieces/min

Each working station works at the same time, it can reach 30-50 pieces/min

Diving Filling Nozzle

Filling nozzle can insert into tubes to prevent filling material from sticking to the tube wall.

Filling nozzle can insert into tubes to prevent filling material from sticking to the tube wall.

High Quality Heating Structure

Can be raised and lowered to ensure consistent sealing height. Suitable for plastic & composite soft tubes.

Can be raised and lowered to ensure consistent sealing height. Suitable for plastic & composite soft tubes.

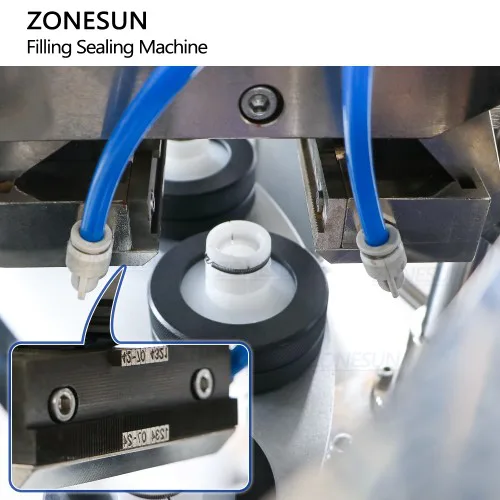

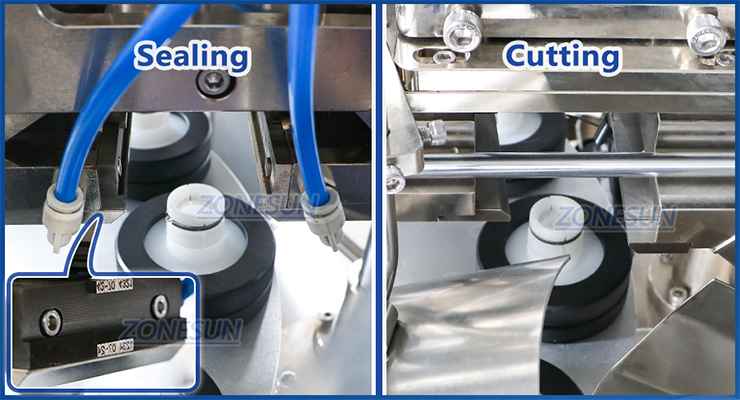

Sealing & Cutting Structure

Can use letter molds to stamp production date or batch number on soft tubes.

Can use letter molds to stamp production date or batch number on soft tubes.

Cooling Machine(Buy separately)

Need to work with cooling machine to ensure packaging quality and safety operation.

Need to work with cooling machine to ensure packaging quality and safety operation.

Piston Feeding Pump

Can supply filling material in time to save working labor

Can supply filling material in time to save working labor