Spirits Wine Pilfer Proof Ropp Filling Line

This filling line is consist of magnetic pump filler, inline ropp capper, sleeve band shrinking machine, laser coding machine, labeling machine and bottle sorting machine to realize the completed packaging work.Machines are customizable based on production need.

Share to

Product Description:

This filling line is consist of magnetic pump filler, inline ropp capper, sleeve band shrinking machine, laser coding machine, labeling machine and bottle sorting machine to realize the completed packaging work.Machines are customizable based on production need.

Product Parameters:

Infeed Bottle Sorting Machine

| Machine model | ZS-LP800N |

| Power supply | 220V/110V 50-60Hz 200W |

| Turntable diameter | 800mm |

| Suitable bottle diameter | 20-100mm |

| Suitable bottle height | 30-320mm |

| Working speed | 40-60 bottles/min(depending on bottle size) |

| Package size | About 1230*1010*1260mm |

| Gross weight | About 141kg |

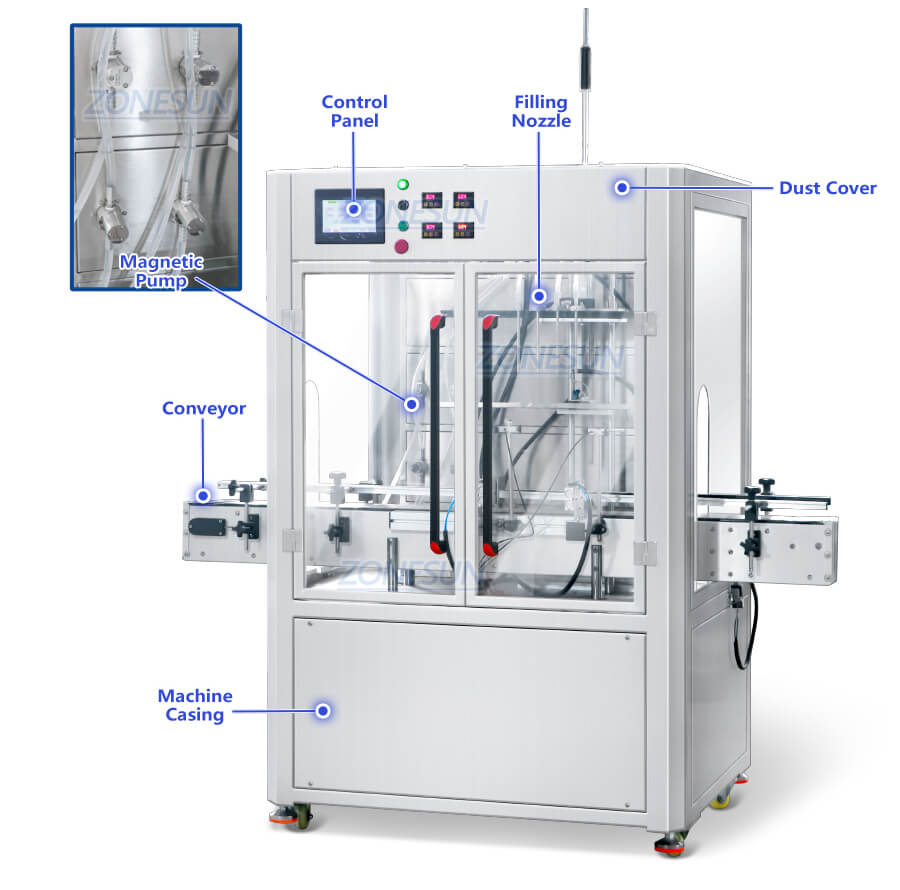

Magnetic Pump Filling Machine

| Machine model | ZS-VTMP80D | ||

| Power supply | 220V-50HZ/110V-60HZ | ||

| Machine power | 2000W | ||

| Container size | φ20-160mm H30-300mm | ||

| Max flow rate | 6000ml/min | 7500ml/min | 12L/min |

| Recommend filling volume | 10-500ml | 30-1000ml | 100-3000ml |

| Material of pump | 316 stainless steel magnetic pump | ||

| Filling speed | About 20-40BPM(depending on filling volume & material) | ||

| Filling accuracy | ≤100ml deviation≤±1ml > 100ml deviation≤±1% ( based on water) |

||

| Size of air compressor connector | OD8mm | ||

| Machine weight | About 285kg | ||

| Machine size | About 1000*900*1860mm | ||

| Packing weight | About 390kg | ||

| Packing size | About 1970*1020*2050mm | ||

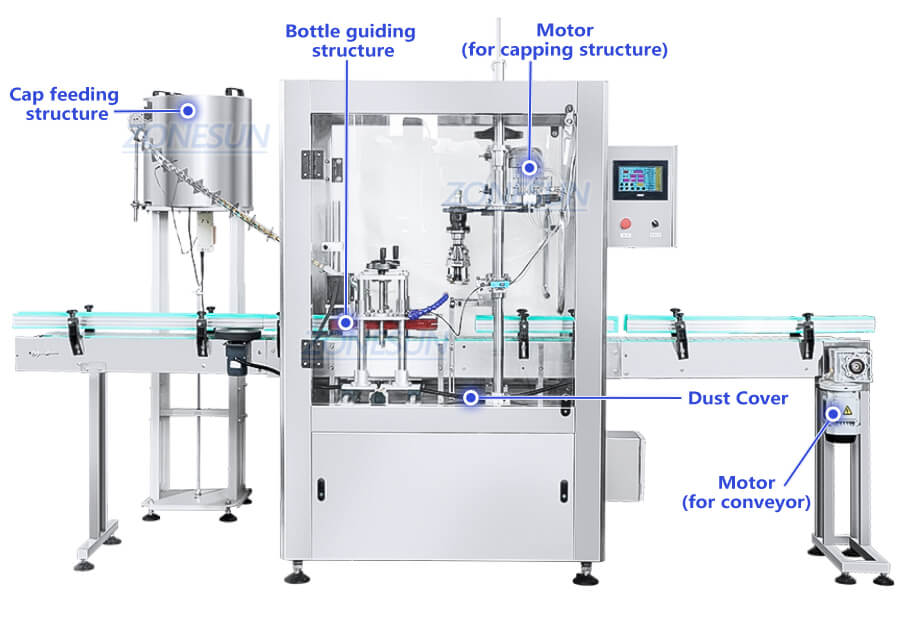

Inline Ropp Capping Machine

| Machine model | ZS-XG440Z |

| Machine voltage | 110/220V 50-60HZ 1KW |

| Suitable cap size | φ25-38mm (Change mold) |

| Suitable bottle height | About 150-320 mm |

| Machine size | About 3550*1700*2250 mm |

| Package size | About 1720*1600*2380 mm(Main Machine) About 550*640*1780 mm(Vibratory Bowl) |

| Package weight | About 640 kg(Main Machine)+123kg(Vibratory Bowl) |

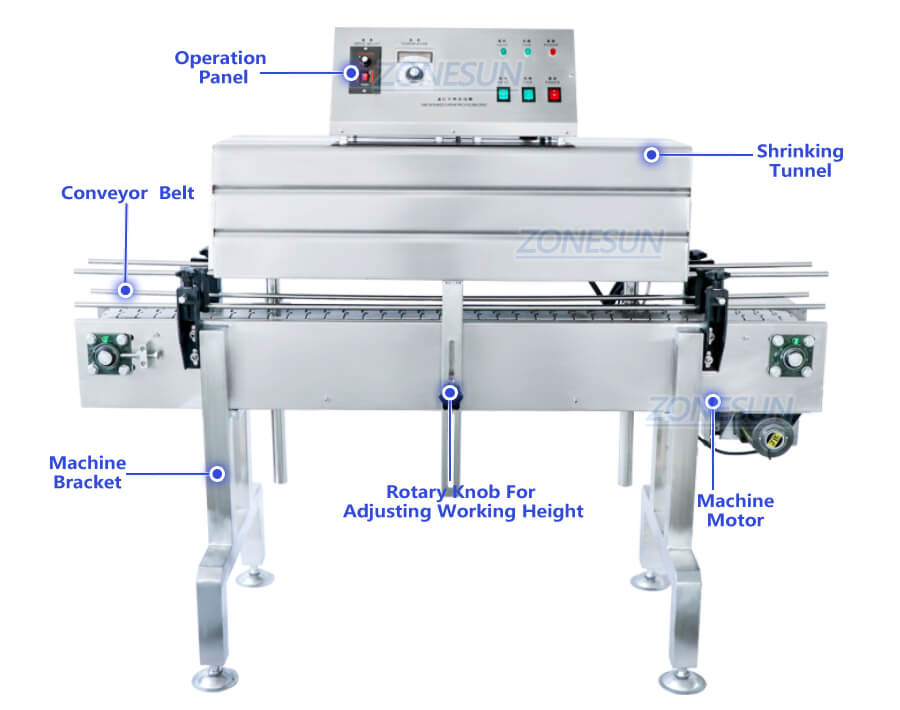

Shrinking Machine

| Machine model | ZS-SX405 |

| Voltage | 220V/380V |

| Power | 6KW |

| Sealing speed | 15m/min |

| Suitable bottle height | ≤350mm |

| Suitable bottle diameter | ≤100mm |

| Machine size | About 1500*500*1270mm |

| Machine weight | About 80kg |

CO2 Laser Coding Machine

| Machine model | ZS-LM1 |

| Power supply | 110/220V 50-60Hz 30W |

| Cooling method | Air cooling |

| Laser | CO2 |

| Port | SD card, USB 2.0, RS232 |

| Wave length | 9.3/10.2/10.6 um |

| Working capacity | PVC tubes: 40 m/min PET bottles: 20000 bottles/h Coated cartons: 35 m/min |

| Marking range | 70*70/90*90/110*110/140*140mm |

| Applications | PET/Acrylic/Glass/Leather/Plastic/Cloth/Rubber(HDPE is not suitable) |

| Language | English, French, Korean, Japanese, Russian, Arabic, etc. |

| Machine weight | About 110kg |

| Machine size | About 1430*565*930mm |

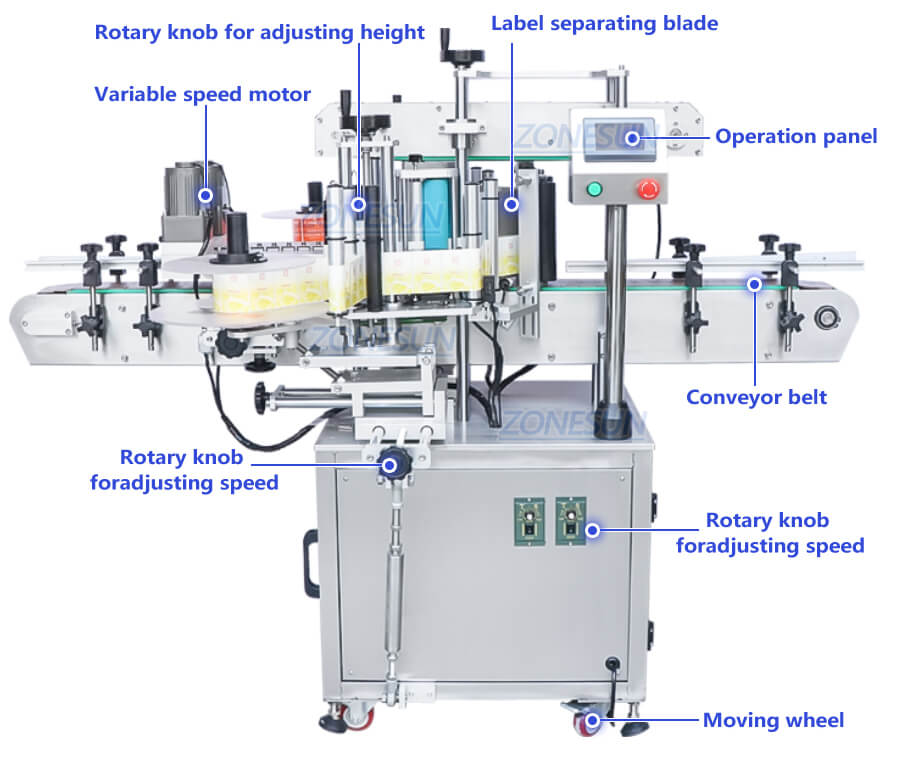

Double Sides Labeling Machine

| Machine model | ZS-TB300V |

| Voltage | 110V-60HZ/220V-50HZ |

| Power | 3100W |

| Working speed | 30-100 bottles/min |

| Labeling accuracy | ±0.5mm |

| Suitable labeling size | ≤200mm(W)(Can be customized ) |

| Roll inside diameter(mm) | Φ75mm |

| Roll outside diameter(mm) | Φ250mm |

| Suitable bottle diameter | φ≤100mm H≤350mm |

| Conveyor size | About 1800*100mm |

| Machine size | About 180*1250*1450mm(L*H*W) |

| Package size | About 1850*1135*1560mm(L*H*W) |

| Net weight/Gross weight | About 213kg/268kg |

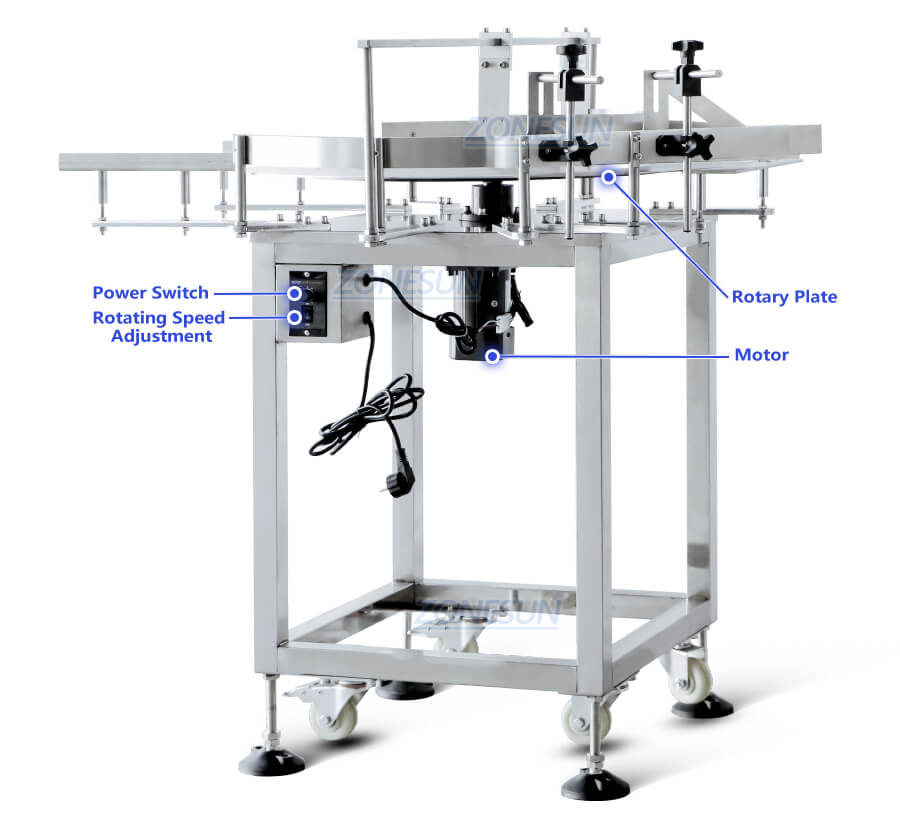

Outfeed Turntable Machine

| Machine model | ZS-SP800S |

| Voltage | 220V 50Hz (110V can be customized) |

| Power supply | 200W |

| Bottle specifications | Square bottle/round bottle |

| Conveying speed | 0-20 revolutions per minute(adjustable) |

| Turntable diameter | 800mm (Customizable) |

| Dimensions | About 550*550*990mm |

| Package size | About 1050*1000*1130mm |

| Net weight/Gross weight | About 93kg/120kg |

Product Details:

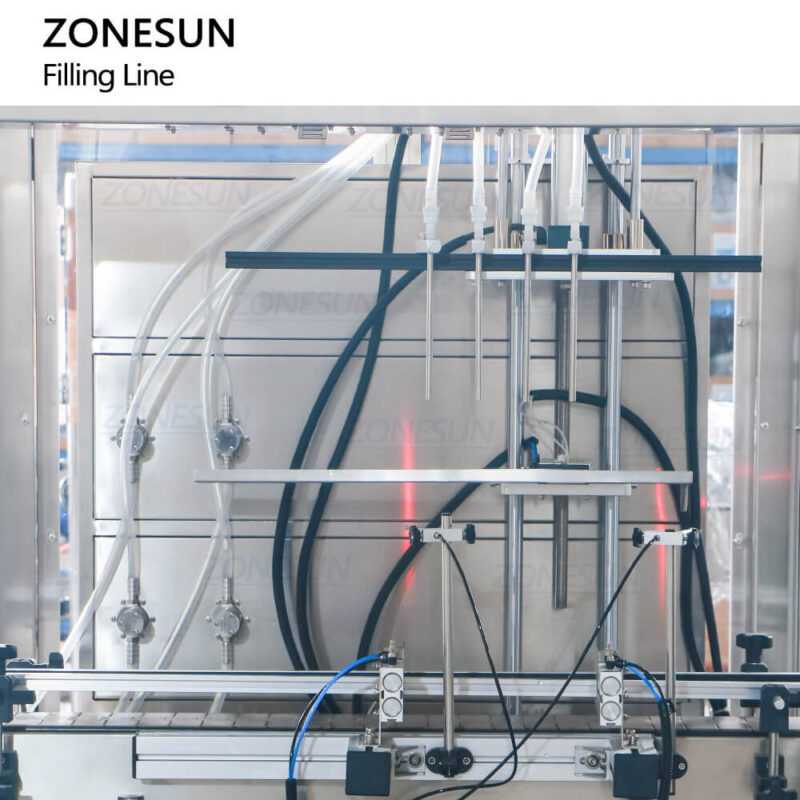

Diving Filling Nozzles

Multi filling heads are customizable based on production needs. Diving nozzles can ensure filling accuracy.

Magnetic Pump

Made of 316 stainless steel magnetic pump, it ha high filling accuracy and suits weakly corrosive liquid.

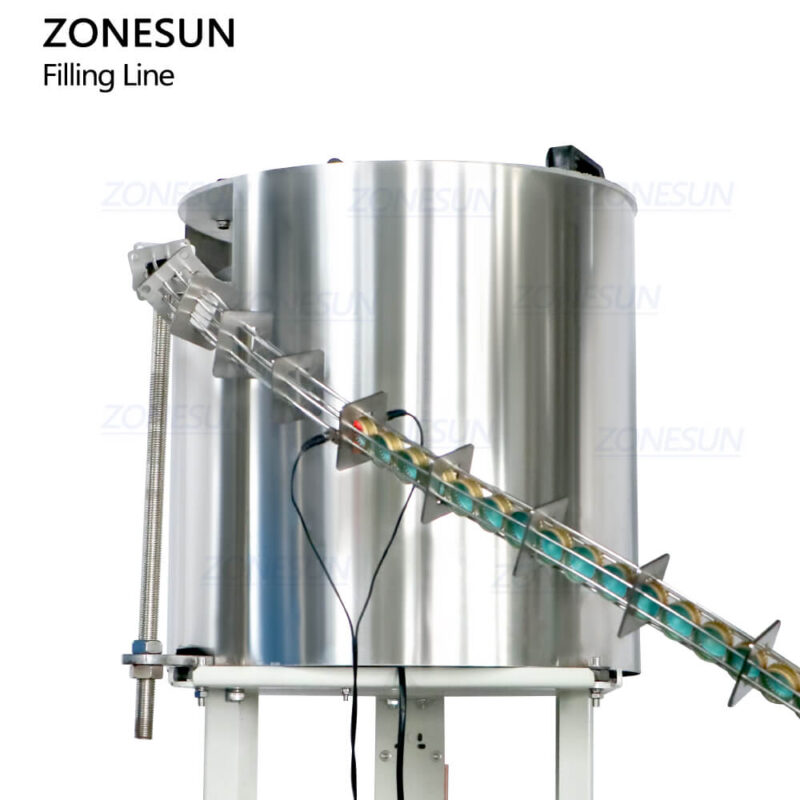

Cap Vibratory Bowl Sorter

This can supply ropp caps in time, guide rail will help to put caps onto bottles to improves capping accuracy.

Capping Structure

It is made of high quality material, this provides a balanced, symmetrical pressure and suitable for 25-38mm Ropp Caps.

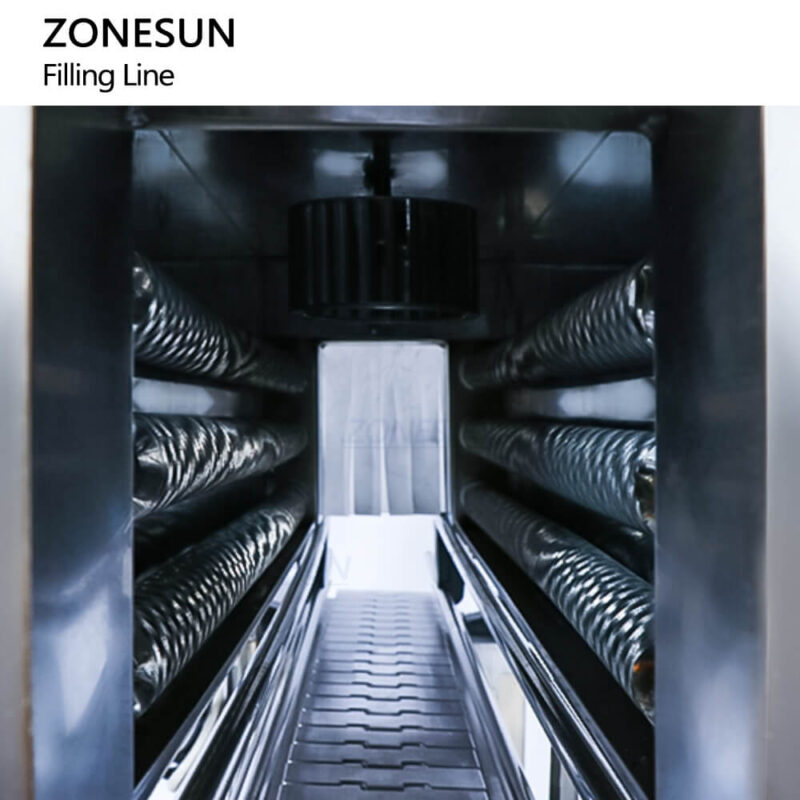

Shrinking Tunnel

Suitable for sleeve band shrinking, the heat can circulate evenly,make the product can be wrapped well.

Labeling Structure

With bottle guiding structure, it is suitable for sticking labels on double sides of flat bottles.Labeling position is adjustable.

Laser Coding

It has large scanning angle and high speed, suitable for coding QR code, batch number, logo on plastic or glass bottles.

Bottle Turntable

Size of turntable machine is customizable based on production, saves working labor.